Description

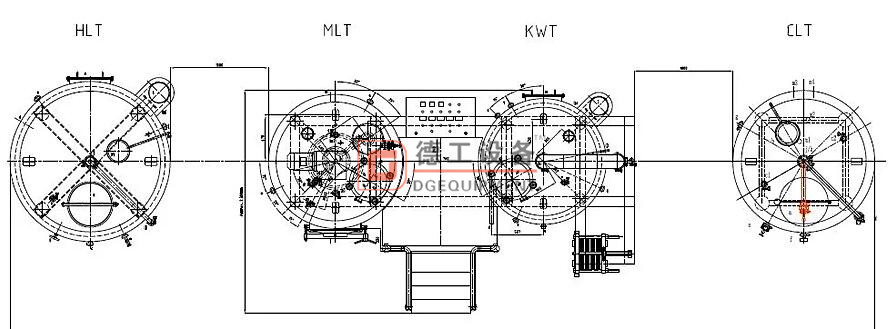

Mash (M) / Lauter tun (L)

Kettle (K) / Whirlpool (W)

Brewery equipment tanks

Multi-step infusion mashing

Multi-step mashing procedure includes a series of rests at various temperatures in a mash mixer. From one step to the next the temperature is increased to the desired value.

The main advantage of the temperature-programmed mashing is that both specific enzyme activity and fermentability of the wort can be promoted by controlling the temperature and duration of stands at selected points.

Step mashing programme includes 6 steps with the possibility of time and temperature setting. Wort recirculation and rake rotation can be set for each step to ensure a homogeneous mash temperature.

- Heat exchanger

- Pump

- Electric box with touch screen control panel

- Manifold with butterfly process valves

- Inlet for decoction mashing

- Rake plow with motor(adjustable rotating speed)

- Wort filter before heat exchanger

Breweries tanks for sale

Implementation of CIP cleaning

Integrated CIP system provides two different cleaning options:

Option 1: Rinse the system with water from the hot water tank. Open corresponding valves to create circulation of hot water and set the desired working speed of the pump.

Option 2: Rinse the system or individual tank with prepared cleaning substance from external source via drain connection.

Integrated pumps

The system includes several centrifugal sanitary pumps: for hot and cold water tank, for lauter tun, for mash

mixer, for kettle and whirlpool. The number of pumps depends on the brewhouse model.

Brewery equipment Cellar tanks operations

Brewery equipment Cellar tanks operations

Cellar tank:Conical fermenters、Unitanks、Bright beer tanks、Larger horizontal tanks

Standard configuration of fermentation tanks

Cylindrical pressure tanks with cone bottom

-Double wall design with insulation

-Laser welded coolling zones in the tank jacket and tank bottom area

-height adjustable tank legs

– oval manway on the tank cover

– safety valves (overpressure and vacuum),

– removable CIP tube with spray ball, butterfly valve

– additional connection on the removable CIP tube, with ball valve,

– pressure gauge,

– level indicator,

– rotating racking port

– sample valve,

– welded thermometer well (additional equipment for temperature regulation available as option: temperature regulator, connecting module, regulation valves),

– bottom drain port

Standards in the beer brewing and beverage industry are very high.

we design and manufacture various types of storage and fermentation vessels which are used under

atmospheric pressure. All vessels are manufactured according to the export stansard which ensure a safe and high quality working vessel.

In designing and manufacturing equipment, our customers’ requirements and requirements of good engineering our the top priorities in the manufacturing process.

Brewery system details

Platform & sight glass & spray ball

Hydrator & Stirring & electric heating tube& raker

Contact us

Ready to Get Started Building Your Dream brewery?

Contact DEGONG Alice Today!