Description

Features

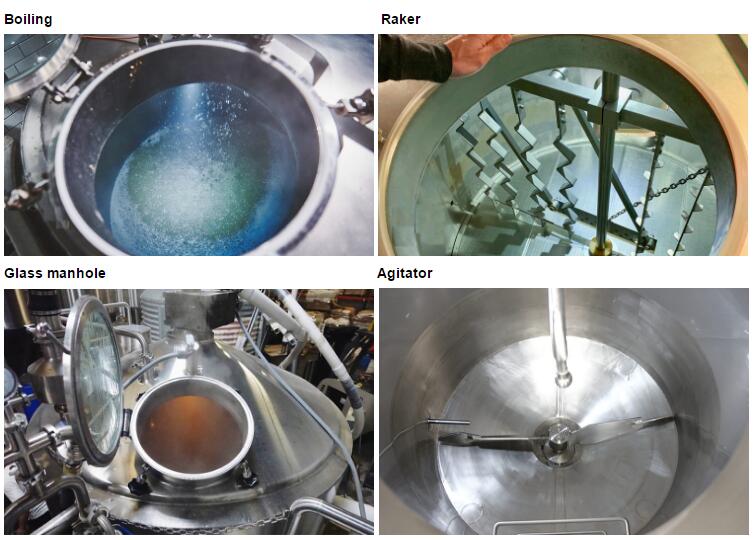

– All tanks are made of food grade stainless steel 304.

– Adopting advanced world famous brand components in electric parts and operation parts.

– ABB motor for wort pump

– ABB/Siemens motor for raker and blender

– PLC automatic control method

– Inner surface treatment: welds grinded to Ra 0.4µm without dead corner

– Outsourcing surface: weld polishing processing

– All welding are used argon gas protection welding. It will help to reduce the oxygenation and protect the joint. Our welders has many years experience in welding and they adopt the most popular welding way–TIG welding.

– TC connected CIP arm with 360° coverage spraying ball

– Dished top and conical bottom

2 vessels mashing system of industrial beer brewery equipment

3 vessels mashing system of industrial beer brewery equipment

beer fermentation tank of industrial beer brewery equipment

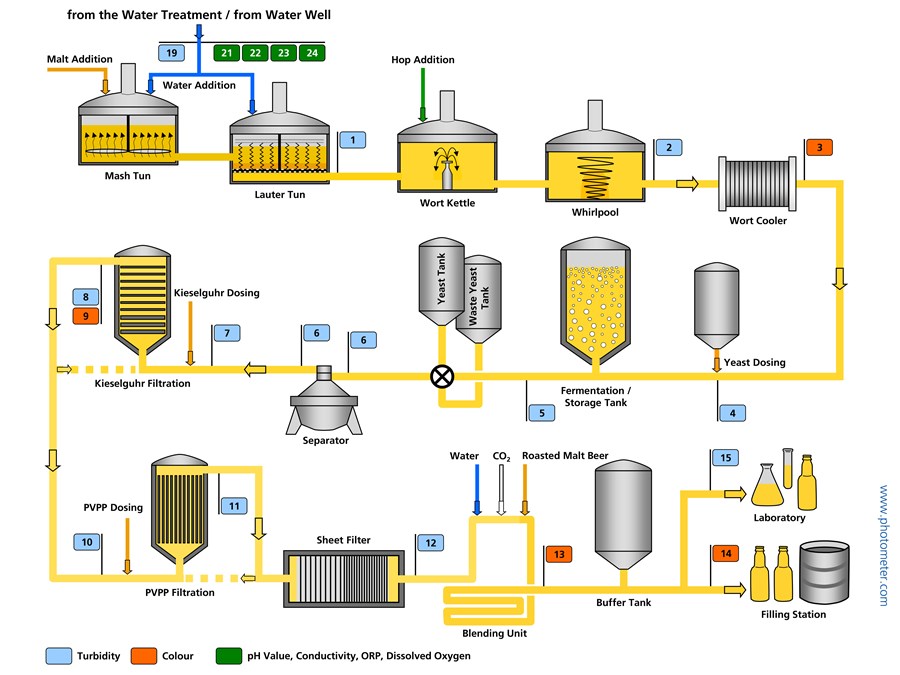

Beer production

Technology of “commercial beer brewing equipment for sale” includes the following stages:

– Malt milling – the germination of cereal grains (usually barley), drying and cleaning of germs,

– Mashing – malt is ground and mixed with water. The mixture then becomes sweet taste,

– Mash filtering – mash is pumped into the filter – vat, where it is divided into wort without hop and spent grain,

– Wort boiling – the wort with hops, and other ingredients, cooked for 1-2 hours,

– Clarification of the wort – wort is pumped into a whirlpool to remove insoluble residues of barley and hops,

– Cooling and aeration of wort – the wort is pumped into a fermentation tank,

– Fermentation – simple sugars in the wort with yeast transformed into alcohol and carbon dioxide,

– Filtering – beer is filtered from the remnants of yeast,

– Pasteurization – some beers are pasteurized – heated to a temperature of 68-72 ° C, for longer storage.

Beer brewing progress

Component of industrial beer brewery equipment

|

1 |

malt milling system |

malt miller machine grist case |

|

2 |

Mash tank/lauter tank |

|

|

3 |

Beer fermenters |

|

|

4 |

Cooling system |

Ice water tank |

|

5 |

CIP cleaning system |

disinfection tank & alkali tank &cleaning pump etc. |

|

6 |

Controller |

Control system, we have PLC automatic and semi-automatic, the elements brand include LG, Siemens and so on. |

|

7 |

Kegging system |

kegging system ( keg washer and keg filler machine), the control system brand is Siemens. |

CIP system with insulated and control panel

CIP system with insulated and control panel

Control panel of PLC,All of the component is Siemens,Omron or Schenider

Control panel of PLC,All of the component is Siemens,Omron or Schenider

Company

DEGONG Equipment Technology Co.,Ltd Jinan is a professional beer brewing equipment manufacturer,which set designing,production,installation,brewing,after service in one.All of our products with strict quality control before out of the factory.

Credibility and high quality are the life of our company!

1.Factory

2.Exhibition in Germany

We attend Germany exhibition in Germany in 2016 and 2017

3.Certification

We have obtain CE&ISO&TUV certification

4.Production

We have the most professional manufacturing team

More information of craft brewery equipment

1.Electric power:It can be customized according to customer’s local condition.Such as 220V,230V,380V,430V; 50HZ or 60HZ;3 phases or single phase.

2.Price:Every customer has different requirement,so we need to confirm your requirement first,then give you price.Such as some customer require steam heating,some customer require electric heating;Some customer require 2 vessels brewhouse and some customer require 3 vessels brewhouse;Some customer require top manhole for fermentation tank and some customer require side manhole.So even both 1000L equipment,there price are different.So we need to confirm your detailed requirement first.

3.How to see if your company is trust?

We have sold many equipment to EURO.We can give you our customer’s contact information,you can listen to their advice or visit their brewery.

4.How should we do if we don’t know how to brew beer and install equipment?

We will dispatch engineer to install equipment and teach you how to brew beer freely.

If you have interest,please get in touch with me freely.