Description

Beer fermentation tank is also called CCT, fermenters are made of SUS 304, for fermentation and maturation of beer. We design, manufacture all variety fermenters from 500L to 30000L . With all the necessary valves, connections, microbrewery fermenters are the CE certification.

Basic Features

-Head space: 25%

-Thickness: Inner shell 3mm;outer shell 2mm

-100mm insulation

-Dimple cooling jacket with inlet and outlet

-Top dry hopping

-Shadow less side man way

-Relief valve

-CIP connections

-Racking arm

-Temperature and pressure gauges

-Level gauge, carbonation stone, sight glass as option

What is unitank?

Fermentation tanks, or more commonly fermenters, are key components in beer brewing. Fermenters are specialized tanks designed to precisely control temperature and maintain the optimal conditions for fermentation, which occurs once the wort has been transferred from the brewhouse to the fermenter; a conical-bottom design is highly recommended for fermenters allowing for easier yeast harvesting.

What is a beer bright tank?

Beer bright tanks are key components in the production of beer and are primarily used to clarify and carbonate beer. Beer bright tanks are the final stop in the brewing process after leaving the brewhouse and fermenters. They can also be used for both the storage of finished beer for later canning, bottling, and kegging and as serving vessels allowing unpackaged beer to be poured and served directly from the beer bright tank

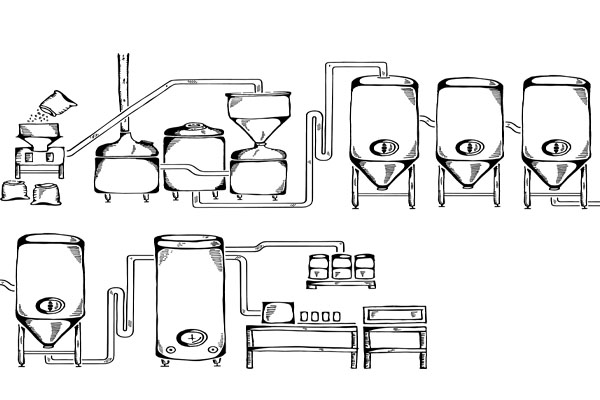

Beer brewing process:miller-mashing-fermenting-maturation-package

FAQ

1.Can your brewing equipment make both lager and ale?

A: Yes, our beer brewing equipment can make both lager and ale.

2.How to achieve temperature control?

A: The PLC or digital displayer could control the temperature by connecting with the PT 100 sensor. The brewing tanks with rock wool to keep warm, the fermenters and bright beer tank with PU as cooling jacket to keep cool.

3.Is it possible to supply installation in our country?

A: Yes, we could supply our clients over sea service and direct the installation and brewing.

4.What type of control system?

A: Our control system is PLC control, also pass the CE.

Contact information:you can get a detailed quotation from us you desire,welcome