Description

2-vessel beer brewhouse equipment

2 Vessel Brewhouse

Mash/Launter Tun + Boil Kettle/Whirlpool Tun

Mash/Lauter Tun/Hot Liquor Tank Combi vessel + Boil Kettle/Whirlpool Tun

Mash/Lauter Tun + Boil Kettle/Whirlpool + Hot Liquor Tank

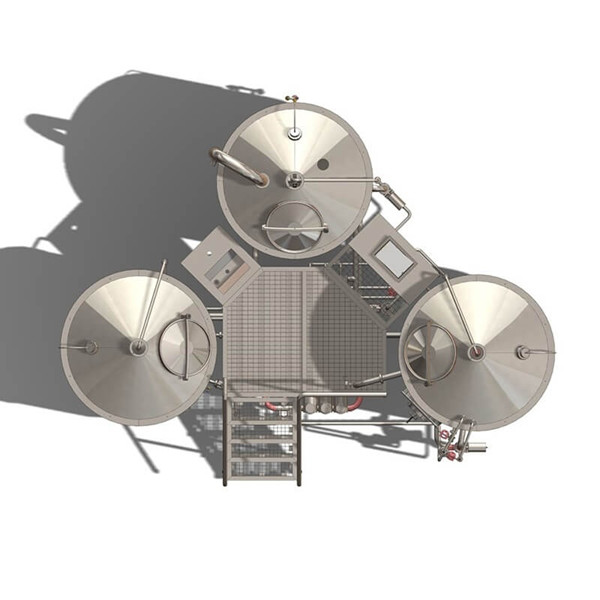

3-vessel beer brewhouse equipment

3 Vessel Brewhouse

Mash/Lauter Tun + Boil Kettle + Whirlpool Tun

Mash (kettle) Tun + Lauter Tun + Boil Kettle/Whirlpool Tun

4-vessel beer brewhouse equipment

4 Vessel Brewhouses

MashTun + Lauter Tun + Boil Kettle + Whirlpool Tun

| Main Configuration: |

1. 35 HL mash tun with steam heating

-2mm exterior shell and 3mm interior shell

-Glass manway

-Agitator with VFD controled motor and turbine reducer

2. 35 HL lauter tun

-2mm exterior shell and 3mm interior shell

-Glass manway

-Grain rake with VFD controled motor and turbine reducer

-Automatic lifter of spent grain scraper blade

-Inline wort lauter sight glass

-Laser cutting V-wire False Bottom/Filter

-Bottom mounted grain outdoor

3. 35 HL brew kettle with steam heating

-2mm exterior shell and 3mm interior shell

-Glass manway

-Agitator with VFD controled motor and turbine reducer

-Sanitary leveling sight glass

-Steam vent with condensate ring for kettle stack

4. 35 HL whirlpool tun

-2mm exterior shell and 3mm interior shell

-Glass manway

-Anticlockwise Tangential whirlpool inlet in Northern Hemisphere

-Clockwise tangential whirlpool inlet in Southern Hemisphere

5. Other auxiliary equipment

-70 HL hot liquor tun with steam heating

-flexible auger/bucket elevator

-2450L hoppper and a malt hydrator

-Pneumatic valve

-Flow meter

-Hop back

-Sink and platform

-35m2 heat exchanger

-PLC control with touch screen

According to client’s needs, various combinations of brewhouse can be offered as followings:

Heating Methods

Steam Heating: dimple plate jacket with inlet/outlet fittings for steam heat transfer;

Electrical Heating: use electrical heaters to heat the medium in the jacket

Gas fired Heating: use gas burner at bottom to heat tank directly

| Our advantages : |

Guaranteed quality & certification:

We own a excellent production team with superb professional skills for cutting, welding, polishing, testing etc.

Every equipment will be tested strictly before delivery.

Reliable performance:

By providing turnkey solutions for compact and industrial-style craft breweries to customers’ specifications and future expansion with decent craftsmanship and reliable performance, we received high comments and repeated orders from our customers.

Good know-how:

We have good know-how about design of a brewing system, plus keeping study about craft brewing. All the brewhouse are customized according to brewer’s craft and building limit.

| Contact information : |

If you have any question,please feel free to contact me.