Description

The beer brewhouse is the heart of the whole beer brewing process. Each stage in the production sequence decisively influences the quality of the beer, flavor stability and yield. Among all the brewing systems,the configuration of beer brewhouse is the most different. The beer brewhouse is composed of four functions, namely: mash, lauter, boiling and whirlpool. These four functions can be completed in 2 or 3 tanks,so we have 2/3/4 vessels beer brewhouse.

500L brewery equipment

2-vessels brewhouse of 500L brewery equipment

500L Mash/Lauter Tun + 500L Boil Kettle/Whirlpool Tun

500L Mash/Lauter Tun + 500L Boil Kettle/Whirlpool + 1000 L Hot Liquor Tank

3-vessels brewhouse of 500L brewery equipment

500L Mash/Lauter Tun/Hot Liquor Tank Combi vessel + 500L Boil Kettle/Whirlpool Tun

500L Mash/Lauter Tun + 500L Boil Kettle+500L Whirlpool Tun

Mash/Lauter Tun + 500L Boil Kettle+500L Whirlpool Tun+1000L hot liquid tank

4-vessels brewhouse of 500L brewery equipment

500L Mash tun+500L Lauter Tun + 500L Boil Kettle+500L Whirlpool Tun+1000L hot liquid tank

500L Mash tun+500L Lauter Tun + 500L Boil Kettle+500L Whirlpool Tun

Hot liquor tank is optional,you can choose it or not according to your requirement

Heating method

Beer mashing is a process that requires heating. This process can be achieved by electric heating, gas heating or steam heating. Customers can choose the appropriate heating method according to their specific conditions.

2-vessels beer brewhouse introduction

1.Mash/lauter tank

Mash/Lauter tun is a vessel used in the mashing process to convert the starches in crushed grains into sugars for fermentation. The saccharification is a progress of raising temperature, so our brewhouse needs insulation to maintain the temperature in the tank.

The mash/lauter tank should have a false bottom to separate the wort from the grain.When filtering,the grain may clog the filter plate, so we usually have backflush pipes at the bottom of mash/lauter tank.It also should have a raker,so that is can loosen the spent grain layer that has become tight due to filtering

2.Boiling Kettle/Whirlpool tun

The boiling is a progress of sterilizing wort, releasing of hop flavours, bitterness and aroma compounds through isomerization, After boiling, the hopped wort settles to clarify in the same vessel, there is a tangential inlet of wort on the vessel.

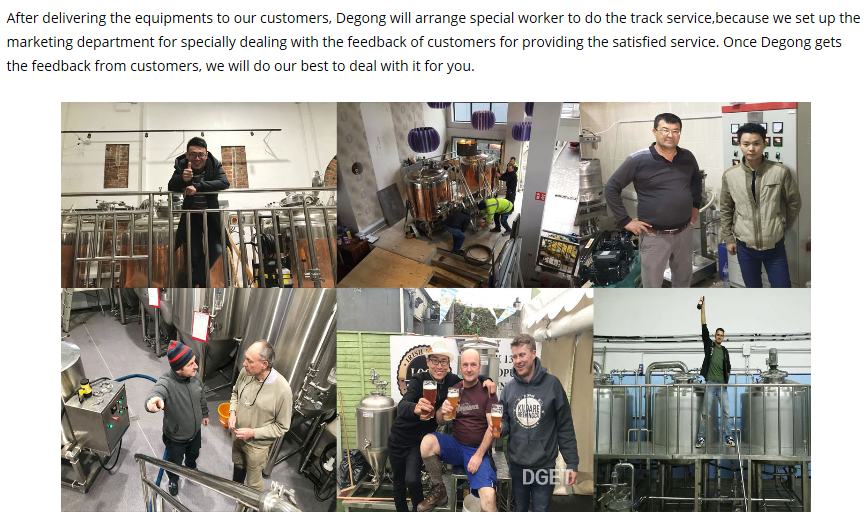

If you want to know more details,welcome to contact me.