Description

DGET breweries offer thoughtfully designed equipment that make brewing easier. Our commercial line of kettles are designed for high efficiency and and our commercial line of mash tanks are loaded with features which simplify maintenance and are designed for ease of use.

Each of our brewhouses is designed with control system, brewing platform, water blending, pumps, heat exchanger, and all piping.

Customizations are easily possible, and we make every effort to make sure the systems conform to any unique processes you might have in your production.

Customized Brewery brewhouse in DEGONG’S plant

|

Commodity |

7BBL BREWHOUSE |

| Heating method |

Electric/Steam heating(electric boiler;gas boiler; diesel boiler) |

| Structure | 2-vessel: mash/lauter tun & brew kettle/whirlpool tun |

| Usage |

Pub/hotel/restaurant beer brewery equipment Micro beer brewery plant equipment |

| Cleaning | CIP arm, 360° spray ball |

| Control |

Semi-auto control cabinet |

| Interior & Exterior & Insulation | Stainless steel 304, thickness 3.0mm

Stainless steel 304, thickness 2.0mm Polyurethane, thickness 100m |

| Others |

False bottom With lauter rakes Side spent grain manway Glass top manway With tangent whirlpool inlet Efficient centrifugal wort pump |

Spent grains hatch with Slide

As an important part of beer brewing, fermenter ferments the wort from the heat exchanger to fermentation.The cone portion of the fermenter is 60 degrees, making it easier to collect yeast and obtain clear beer.

Main Features of brewery fermentation tanks:

- 7BBL operating volume; 1000L max volume

- All connections are fully welded Tri Clamp fittings

- 0.12- 0.15Mpa operating pressure; 0.3Mpa design pressure

- Pressure gauge

- Versitile port for dry hopping, CIP, and the pressure relief valve

- Sampling valve

- Thermowell for thermometer

- Carbonation stone

- Blow off cane

- Polyurethane 100mm insulation jacket

- Custom ss butterfly valves with racking arm

- Stainless lower shelf

- Adjustable feet

Brewery equipment fermenting vessel’s components

Side manhole;supporting legs;spray ball;thermometer

Tank and System Controls

We can offer complete tank and system controls for any critical parameter of your process including:

- Glycol chilling and cooling controls – solenoid, check valve, or pressure sensor actuated

- Steam or other heating controls – globe, gate, pressure sensors, or solenoid actuated

- Filtration systems and controls – Water flow controls, backflow preventers

- Programmable digital controllers for valves, solenoids – temperature, pressure and flow controls

- PLC controlled systems – standard or custom software control packages

- Semi automated or automated – other control features and options available

Glycol chiller line

Our glycol chiller arrived at the brewery – it is a large and important piece of our brewery. The glycol chiller pumps cold glycol through the cooling jackets on our 10BBL fermenters. This controls the beer temperature throughout fermentation to ensure you get a tasty beer.

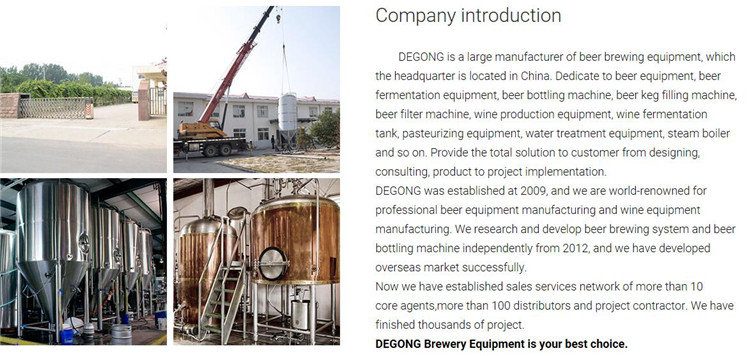

Company introduction:

Welcome to visit our website and contact me to get more useful brewing knowledge ,Cheers!!!