Description

Craft beer brewhouse working process

Mashing is the process of combining a mix of milled grain and water and heating this mixture in a vessel called a “mash tun”. Second process, you need transfer the mixture of grain and wort into Lauter tun. You can get clear wort from this vessel. Thirdly, let’s pup the clear wort into a vessel named Kettle, in which will happen many key process including: wort boiling(usually 60 minutes), hops adding. At the end of the boil, the wort will be into whirlpooling, forcing the denser solids (coagulated proteins, vegetable matter from hops) into a cone in the center of the Boiling/Whirlpool tank.

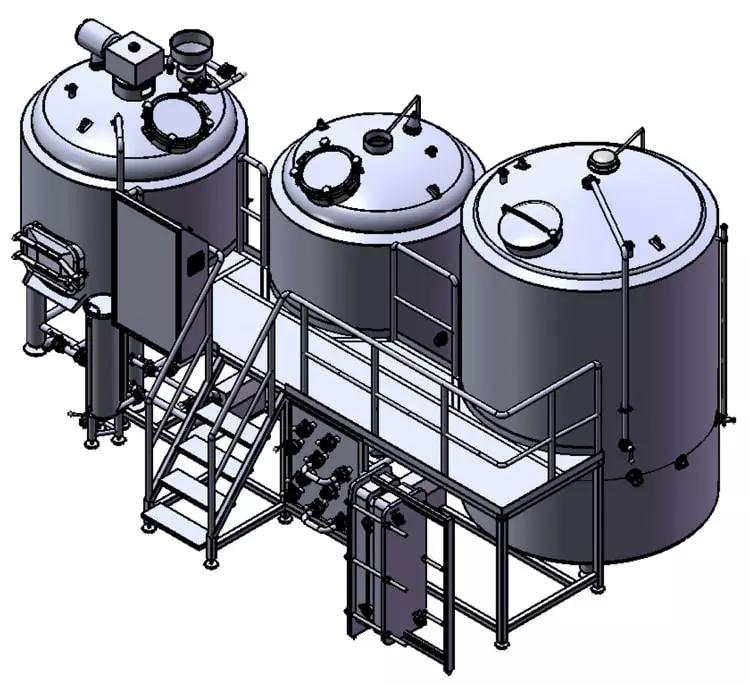

3-vessel craft beer brewhouse:mash/lauter tun+boiling/whirlpool tun +hot water tank

3-vessel craft beer brewhouse:mash/lauter tun+boiling/whirlpool tun +hot water tank

|

3-vessel craft beer brewhouse |

Mash tun | 7BBL (with 25% head space) |

Top mounted manhole Steam Jacket for optional |

| Lauter tun | 7BBL (with 25% head space) |

Side mounted grain outdoor with grain chute Laser cutting V-wire False Bottom |

|

| Boiling/whirlpool tun | 7BBL (with 25% head space) | Steam heating | |

| Tangential whirlpool inlet | |||

| Plate heat exchanger |

8m2 (Effective area) |

Completely 304 SS Corrugated plates | |

| Wort pump | 3m3/h | ABB, Sanitary SUS304, VFD control | |

| Pipe and fittings | As designed | completely SS304, Work Platform is included |

3D 3-vessel craft beer brewhouse

3D 3-vessel craft beer brewhouse

Craft beer brewhouse details

Regarding the brewhouse of beer brewing equipment, we have two vessels, three vessels and four vessels brewhouse for your choose.

Mash tun:

Mashroom-shaped head or dish head on the top, 80mm PU insulation, Agitator with VFD controlled, SUS or glass manhole, CIP cleaning device, Legs and other pipelines and valves

Lauter tank:

Mashroom-shaped head or dish head on the top, 80mm PU insulation, Raker arm with speed controller, Side mounted grain outdoor with grain chute. Easy clean and detachable sparging spray ring, Leaser cutting false bottom, SUS or glass manhole, CIP cleaning device, Legs and other pipelines and valves

Boiling/whirlpool tun:

Mashroom-shaped head or dish head on the top, 80mm PU insulation, Heating: electric, steam or direct fire heating, Tangential whirlpool inlet, SUS or glass manhole, CIP cleaning device, Legs and other pipelines and valves

spent grains hatch, sight glass, raker with VFD, ring and cleaning ball

spent grains hatch, sight glass, raker with VFD, ring and cleaning ball

Packing & Shipping

1. All tanks will be packaged with soft protection material and mounted on strong carbon steel frame

2. All accessories and spare parts will be packaged with separate box.

3. After loaded into containers, all equipments will be well fixed to the containers.

4.Transportation mode: ocean, railway or air transportation

If you have interest, please feel free to contact me.