Description

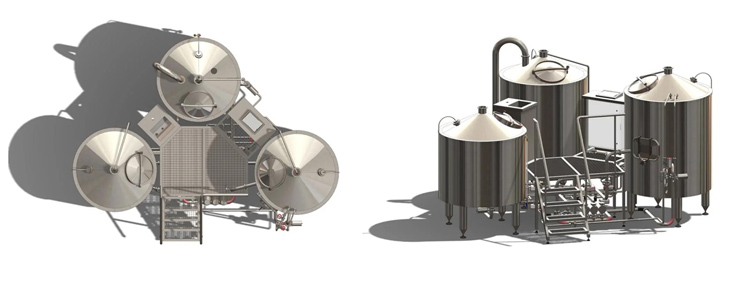

3-vessel beer equipment brewhouse system description |

Mash tun

Low pressure steam jacket with PLC controlled temperature control for optimum profile capability

VFD speed and function controlled, custom engineering mash mixer for low sheer, efficient mash mixing designed to handle high gravity brews

Lauter tun

- Integrated, VFD speed and function controlled rake system designed to cut and lift grain bed to maximize extract yield, reduce lautering time and automate grain out processes

- Custom designed wedge wire false bottom designed to maximize yield and minimize grain pass-through

- Grain out access manway for easy and efficient grain out processing

- Multipoint wort collection design for uniform bed formation and high yield extract collection

Boiling/whirlpool tun

- with integrated steam jacket and temperature control

- Custom designed vessel optimized for rapid boiling and efficient and high yield trub separation

- Low pressure steam jacket with PLC controlled temperature control for efficient and vigorous boil control

- Tangential inlet for proper centrifugal force for efficient trub separation

- 316L Sanitary Pumps with VFD Controls

- 316L Stainless Steel Plate Heat Exchanger

- Manual Sanitary Butterfly Valves

- Ergonomic and efficient 304 stainless steel Brew Deck with easy access to all vessels and brewing functions

2000L 3-vessel beer equipment

3-vessel beer equipment fermentation system description |

- Our range of hygienic Jacketed Conical Fermentation Tanks (Beer Fermenters) are available from 1 Barrel to 100 Barrels.

- The conical fermentation tanks have a dish top with a cylindrical body.

- All tanks are food-grade stainless steel 304 with a 3 mm thickness for 3BBL-70BBL.

- The cooling system is a dimple jacket tested to 6 bar with a working pressure of 5 bar and the tanks are insulated with high-density polyurethane.

- All tanks are designed for up to 15 PSI (internal pressure) and tested at 30 PSI.

stainless steel fermentation tanks