Description

Working with all relevant partners, DEGONG can manage the design, engineering, build and installation of beer brewing equipment that helps you achieve your unique brewing process and replicate it.The full line products including milling, mashing, fermentation, cooling, filtration, filling and other related processes.

Mashing system

- Mush/brewhouse heated via steam,electric or direct fired

- Flexible brewhouse designs to accommodate your available square footage and ceiling heights

- Custom can design brew houses for sour beer production

- Brewhouse configurations from 2-vessel to multi-vessel designs

configuration deails:

- Material: Inner(SUS304),thickness: 3.0mm;

- External-Jacket(SUS 304), thickness: 2.0mm;

- Cylinder (sharp type, SUS304), thickness: 2.0mm.

- Inner surface treatment: welds grinded to Ra 0.6µm.

- Insulation: Polyurethane-thickness 100 mm.

- Temperature way:Double metal thermometer

- Outsourcing surface: Weld polishing processing

- Jacket Pressure: design pressure 0.3 MPa, working pressure <0.2 MPa.

- CIP 360 degrees Omni bearing cleaning

- Integrated CIP System

- Hot Liquor Tank –Designed and Sized for Double Brew efficiency

- Cold Liquor Tank –Fully insulated and integrated

- Stainless steel 304 pump with ABB or Siemens motors

- Mash / Lauter Tun with grain raker

- Boiling/whirlpool tank with whirlpool port and stir blades

- 304 stainless steel operate platform and stairs

- Plate heat exchenger design pressure :1.0Mpa

3D view of 3-vessel brewhouse equipment

components and accesseries of brewhouse equipment

Fermentation system

Degong’s fermentation tank is certified with ISO,CE and TUV,featuring high quality and being applied in beer bar,restaurant, beverage factory in more than 50 countries all over the world. It will be the best choice for the buyer who want establish the commercial and industrial brewery for brewing the unique taste of beer. Technically speaking, the fermentation system is consisted of fermenter,bright beer tank, yeast tank and other accessories.

Configuration details:

- Material Inner (SUS304)thickness: 3.0mm; Outer(SUS304)thickness:2.0mm

- External-Jacket(SUS304) thickness: 1.5mm;

- Oval head cone bottom, thickness: 3.0mm.

- Surface: Finish2B – cold-rolled, annealed, pickled

- Inner surface treatment: welds grinded to Ra 0.6μm (attached 360 degree Omni cleaning ball).

- Mirror surface finish inside.

- 100% TIG welding with pure argon gas shield

- Insulation: Polyurethane-thickness 100 mm.

- Equipment with : cone 60°resist compression design,dripping 10.Temperature drop.

- Cleaning System: All-round cleaning

- Vessel Pressure: test pressure 3 bar, working pressure 1.5 bar

Cooling system

Cooling system is always consisted of circulation pump, glycol water tank and chiller. How to equip a suitable cooling system depends on the quantity and capacity of fermenters. The glycol water tank is for filling the glycol water. And the chiller is for generating the cooling capacity to reduce the temperature of the glycol water heated by heat generated by fermentation process.

- chiller

- Refrigerant: Freon R404A, Copeland compressor

- glycol water tank

- Glycol water circulation pump, VFD control

- PPR pipe

cold water tank

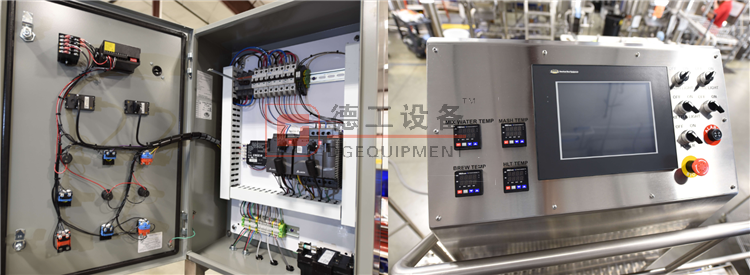

Control system

Control system is the soul of a whole set of beer brewing equipment. It controls the running of each components such as pump, motor and whole brewery system. Degong’s control system is a integrated box which houses the terminals of all components.

- Semi automatic control system or PLC fully automatic control system if requested

- Siemens/Schneider/Omron components

- PC or mobile remote control if requested

- Individual control system for brewhouse system and fermentation system

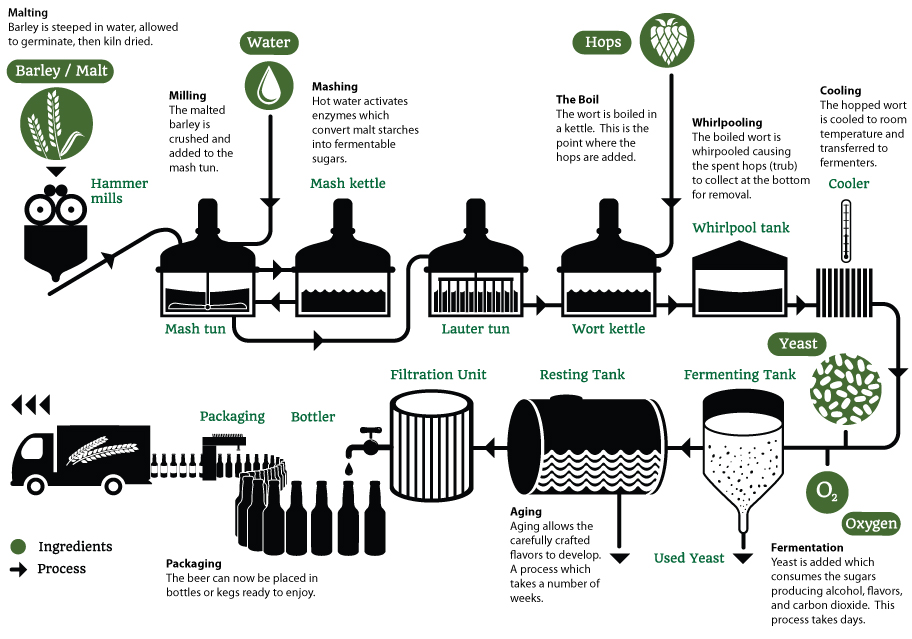

Brewing Process

Our certificate

With the high standard of beer brewing equipment both in row materials and manufactures, DEGONG have passed 4 international certification: ISO9001,ISO14001,SGS ,TUV and CE.

Packing&delivery

Packaging type : standard wooden package

Package details : As usual, we adopt wooden case as package type. It’s suitable for long-distance

FAQ

Q1:What’s the payment you prefer?

A:Our standard payment terms are T/T with 30% deposits and balanced before shipment.

Q2:Do you have technical support after we purchased equipment?

A:We will arrange the professional technician to go to your factory and give the support to help you learn how to install and maintenance the machine or help you to fix the machine when it has problems.

Q3:Where is your factory?

A:Our factory is located in Dezhou City, Shandong province,China. We can pick you up at the airport whenever you want to visit the factory.

Q4:How long time for installation?

A:It’s according to your equipment order, it about 10days to 25 days.

Q5:Where is the port of loading?

A:The port of loading is Qingdao

Contact us

Every Brewhouse is unique and requires different specifications. Please shoot us an email or give us a call for a quote.