Description

| Brewery machinery in stock |

If you are really passionate about brewing and want to consider starting your own business, I offer an overview on how to get started with your own microbrewery.

There are two types, brewpubs and microbreweries. A brewpub is smaller, perhaps 300L/500L. A brewery is larger, perhaps from 1000L to 5000L. The brewery is measured by the brew-kettle, or how much wort you produce in one batch.

2000L or 20hl brewhouse system brewery machinery

2000L commercial brewery machinery |

||

|

The Heating source |

Steam heating |

The steam heating would require a boiler/generator. It heat evenly and fast, also easy to control temperature, not scorch the tank. |

|

Direct fire heating |

The burner and agitator are equipped with kettle. If you adopt decoction mashing way, the wort is easier to scorch. If so, the steam heating is more suitable. |

|

|

Electric heating |

The electric heating behaves well for the volume under500L, saving the investment on the boiler/burner, if there is no condition to use the boiler/burner or it is more economical by using electricity. |

|

|

The structure |

2000L Two vessels |

Mash/lauter tun+Kettle/whirlpool tun |

|

Mash/lauter whirlpool tun+Brew kettle tun |

||

|

2000L Three vessels |

Mash tun+Lauter tun+Kettle/whirlpool tun |

|

|

Mash/Kettle tun+Lauter tun+Whirlpool tun |

||

|

2000L Four vessels |

Mash tun+Lauter tun+Kettle tun+Whirlpool tun |

|

|

The Manway |

Stainless steel |

Affordable |

|

Glass |

Easy to observe the tank inside |

|

|

False bottom/filter |

False bottom/filter |

We use the Laser cutting V-wire False Bottom/Filter.This kind of False Bottom/Filter is more stronger, even and nonpollution of welding.Using this false bottom when lautering, you will find that the grain bed is easy to form well and it will be also easy to clean when you finish the lautering. |

|

Raker |

Raker |

We now use the Long-style rake; the teeth of the rake is varied so that it can agitate the wort lengthways and transversely, plus its length, the rake can help to make the malts mix with the water soon and make the wort flow smoothly and help to form a efficient grain bed for better lautering. In addition, the automatic rake lifting units is optionalfor customer. |

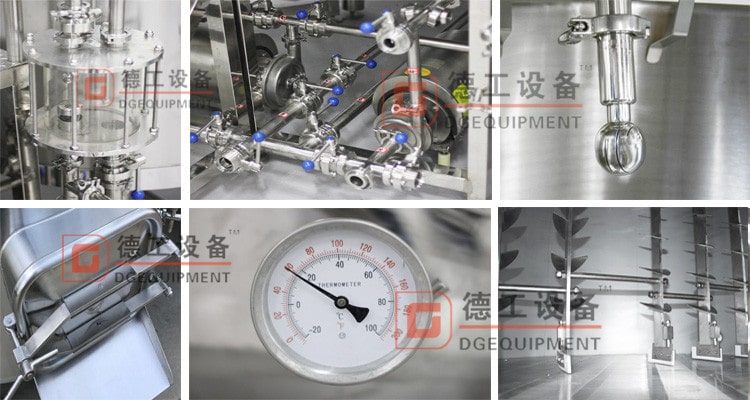

Wort grant;wort pipelins;spray ball… in the tank

Most breweries today use vessels with a conical bottom and a cylindrical top. The cone’s aperture is typically around 60°, an angle that will allow the yeast to flow towards the cone’s apex, but is not so steep as to take up too much vertical space. CCVs can handle both fermenting and conditioning in the same tank. At the end of fermentation, the yeast and other solids which have fallen to the cone’s apex can be simply flushed out of a port.

Brewery machinery 2000L Beer Fermenters

|

2000L Beer Fermenter of brewery system |

|

|

Function |

Wort Fermentation or maturation |

|

Tank Capacity |

2000l or 4000l (+25% Head space minimum) |

|

Interior Shell |

SUS304 full welded; TH=3mm |

|

Exterior Shell |

SUS304 full welded; TH=2mm |

|

Insulation |

Polyurethane; TH=100mm |

|

Glycol Jacket |

Dimpled plate on cone and side |

|

Head and Bottom |

Dished head and 60 degree cone bottom |

|

Sampling valve |

Full sanitary perlick style sampling valve |

|

Safe valve |

Mechanical relief valve 2 bar on CIP arm |

|

Pressure gauge |

Shockproof pressure gauge with two gauges on CIP arm |

|

Beer outlet |

Rotating racking arm and port on cone with butterfly valve |

|

Hopping port |

Dry hopping port on the top of tank |

|

Leg |

4pcs completely SUS304 heavy duty legs with leveling pad and legs support |

Brewing beer also requires more machines, such as water treatment, beer filter, filling machine, etc. If you want a turnkey brewery or just tanks (such as a fermentation tank), please contact me.

| Contact Alice today |

Talk to us about your requirements and we will design a system to work for you and your company.