Description

| 10 BBL brew equipment 2, 3 or 4 vessel |

Two brew equipment with deck

10 BBL brewhouses come in 2, 3 or 4 vessel configurations for ale or lager. All systems come with hot liquor tanks, malt handling and milling.

3-Vessel Brewhouse

When additional batches or turns are necessary, the 3-Vessel Brewhouse is a welcomed improvement over a 2-Vessel set-up. Designed for Brewhouses 10-BBL and higher, an area for a future fourth vessel can be designed into the platform and system. More automated controls are often seen to achieve faster turns and very consistent brews. There are two options for the shared vessel.

Used for Brewhouses 10BBL and larger in size. The shared vessel can vary:

Version 1

Combined Mash/Lauter Tun

Brew Kettle

Whirlpool

With the trend of heavily hopped beers, a seperate and wider whirlpool can be made at address bigger trub piles.

Version 2

Mash tun

Lauter Tun

Combined Brew Kettle/Whirlpool

This is the more traditional set-up for a 3-Vessel Brewhouse

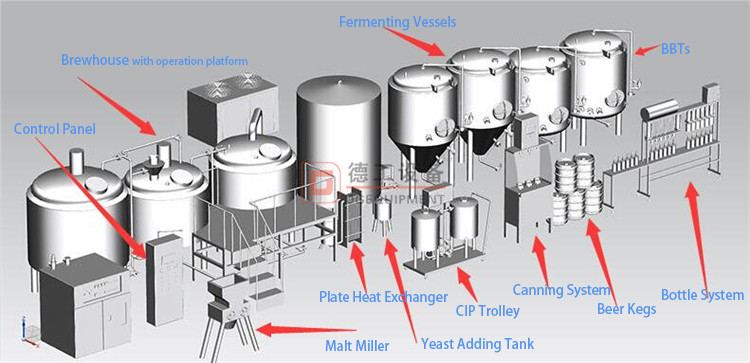

Brewhouse system brew equipment

PRODUCT PARAMETERS

Features: 2, 3 and 4 vessel Brewhouse Systems,such as mash tun lauter,kettle whirlpool,hot water tank

Tank heating: gas heating with gas burner, Electric heating, Steam heating with steam bolier

Top Manways: stainless steel or glass material ;

Grist Hydrator

Heat Exchanger: two stage cooling

Fermenters with top hop additional port or not

Dimple jacket is installed on both cylinder and cone part of the equipment

Yeast tank

Bright beer tanks with cabonation stone

Glycol tank

Chiller: suitable for your cooling square.

CIP cleaning system:50L or 100L

PID control system or PLC control with simens touch screen

Pumps:wort pump,hot water pump,Glycol Pump,CIP pump

Other required brew equipment (fermentation tank, brite tank, beer kegs, etc.)

Fermentation tanks with spare parts,like butterfly,safety vale,drain outlet…

| Fermentation tank parameters | |

| Features:

Dished head and conical bottom Dimple cooling jacket Cladding sheet welded or riveted Insulation with Polyurethane foam Built with stainless steel 304 |

Fittings:

Pressure safety valve Mechanical regulating valve CIP and carbon dioxide outlet Temperature sensor Sampling valve Spray ball Manhole(top or side) Drain Outlet Hops port Pressure gauge Rotating racking arm |

| Contact Alice today |

Talk to us about your requirements and we will design a system to work for you and your company.