Description

| Beer production machine introduction |

DEGONG offers flexible micro/craft beer production machine designs to ensure that optimal efficiency is achieved. Although high-quality beer brewing is mainly related to the experience of the brewer, the quality of the brewing system also plays an important role.Having a high quality beer production machine will ensure that you have the necessary tools to keep the same flavor profile with every batch!

Malt mill

DEGONG supplies you with the malt mill best suited for the type and size of your brewery. We implement the malt mill with a high level of automation, depending on the size of you industrial brewery. This includes the malt conveyor and the corresponding silos.

Remark:the malt mill should finish the crushing in half one hour,so we will recommend you suitable milling machine based on your brewery’s capacity.For 10hl brewery equipment,we recommend 300-500kg/h milling machine

Brewhouse

DEGONG brewhouse offer everything that’s essential for best beer quality. An economical boiling system, a reliable lautering system and high-quality elements for the piping and frequency management of the pumps and motors. Our brew house unit designed in line with client demands ,which combine mash tank,lauter tank,boiling tank and whirlpool tank freely.

Fermentation & storage

DEGONG fermentation and storage tanks comply with all applicable standards. Other quality features include generous and separately controllable cooling zones for perfect fermentation and storage. High-class surface finish and properties prevent areas that are inaccessible for cleaning and guarantee micro biologically perfect brewing.

Cooling system

Cooling system contains glycol water tank,cold water tank and chiller.The cooling system is vital for the production of beer; it controls the Fermentation environment and keep the temperature ideal for yeast throughout the process of conversation of sugar into alcohol.The Refrigeration system is the key system within the fermentation section because it helps regulate and maintain the temperatures of the product during fermentation.

CIP units

The system is employed to clean and sanitize all the brewery equipment including brew house, fermentation tanks and bright beer tanks using specially engineered CIP Spray balls for optimum cleaning of internal surface.

Automatic control

The control of a brewhouse offers the following benefits:the mashing and boiling process runs automatically. All the steps in this sub-process can be operated via the control panel and programmed freely.

Beer sales system

After finishing the brewing progress,then brewers will sell beer in kegs,bottles,cans or dispenser in bar.

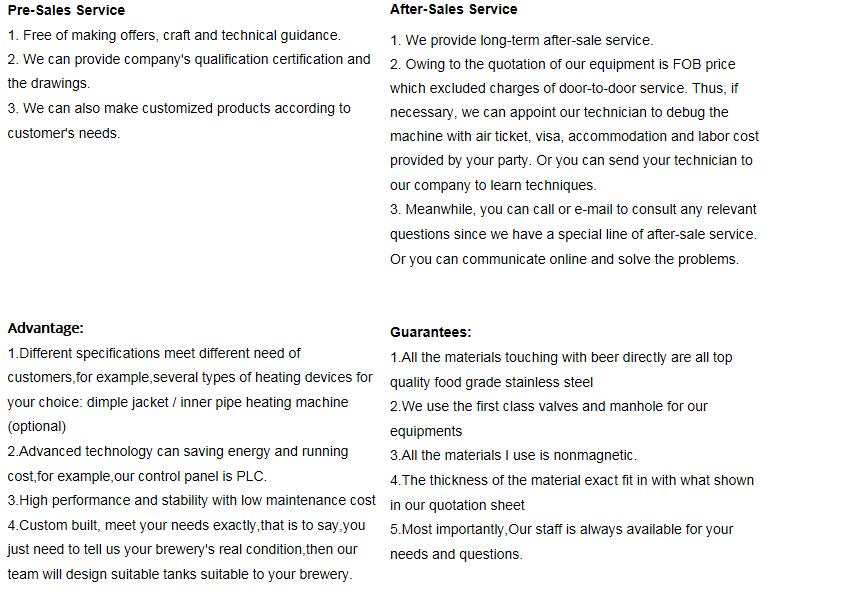

| Our service |

| Certification |

Our equipment is coming with certifications of PED/ISO/CE ,which all reach the food sanitary standard .The quality, specification and function all meet the treaty of contrac

| Company information |

If you have interest in beer production machine,contact me freely.