Description

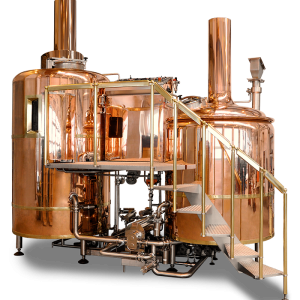

10HL steam heated beer brewing equipment made in Degong

10HL beer brewing equipment is one of the best-selling brewery models in my company. A complete set of beer brewing equipment is consisted of malt milling part, Brewhouse part, fermentation system, cooling system, CIP system, control system and other auxiliary accessories such as kegging machine, bottling machine, etc… Our 10HL beer brewing equipment has been sold to over 30 countries worldwide, especially in European market and USA market. The set of 10HL beer brewing equipment is approved by CE ISO TUV. And the components we use for the set of system are from the world renowned companies such as ABB, Siemens, Omron, etc…

Beer brewhouse of 10HL beer brewing equipment:

Mash/Lauter tun:

– Stainless steel grist hydrator

– Upper and lower steam jackets

– Heavy duty false bottom with pillar support system

– CIP spray nozzles under false bottom

– Multiple wort drain locations

– Fully insulated vessel

– SS CIP high-low rotary spray ball with 360 coverage

– Interior LED light

– Top tempered glass manway

– Side manway for automatic spent grain out

– Automatic variable speed rake system

– SEW/ Siemens motor for rake

Brew kettle/ Whirlpool tank:

– Upper and lower steam jackets

– Tangential wort inlet

– Fully insulated vessel

– SS CIP high-low rotary spray ball with 360 coverage

– Top tempered glass manway

– Interior LED light

Fermentation system of 10HL beer brewing equipment

– 100% TIG welded and sanitary polished

– Design pressure: 3 bar, test pressure: 2 bar

– 4 heavy duty stainless steel legs with adjustable height and leveling pads

– Interior shell: stainless steel 304, thickness: 3.0mm

– Interior (2B) and exterior finished bright polish, sanitary surface

– Tri-clamp sanitary fittings

– Vacuum & pressure relief valve

– Pressure gauge

– Thermometer gauge

– Sample valve

– Lifting lugs

– Ladder hooks. Also designed to hold brewer hose when not in use

– Side manway

– CIP arm and rotary spray ball with 360 of coverage

– Dual zone cooling jacket with glycol water inlet and outlet

– Rotating racking arm and discharge port with valve

– Dry hopping port

– Thermowell with RTD temperature sensor

Services

Brief introduction of Degong

DEGONG is a large manufacturer of beer brewing equipment, which the headquarter is located in China. Dedicate to beer equipment, beer fermentation equipment, beer bottling machine, beer keg filling machine, beer filter machine, wine production equipment, wine fermentation tank, pasteurizing equipment, water treatment equipment, steam boiler and so on. Provide the total solution to customer from designing, consulting, product to project implementation.

Equipment Design and Coordination

DGET will size the boiler and chiller system to ensure they match each individual brewery layout. Piping schematics will be developed for construction by DGET or local contractors. We can also assist the architect and building engineering team with calculations and documentation during the permitting phase of construction.

Installation, Commissioning, Startup

DGET can be involved as much as needed in the installation process of the brewing equipment. A full crew can be on site to perform the full installation or a representative can be on site to oversee a local crew. After installation of the brewing system, DGET can be on site to provide start-up assistance of all the equipment and walk the brewers through the complete brewing process with a water boil. If needed, we would even be happy to assist with the initial batches of beer produced on your new system.

Packaging & Delivery

Packaging Details: standard wooden package

Package Type : As usual, we adopt wooden case as package type. It’s suitable for long-distance transport. According to customers’ special demand, we could adopt sheet iron case and so on.

Contact us