Description

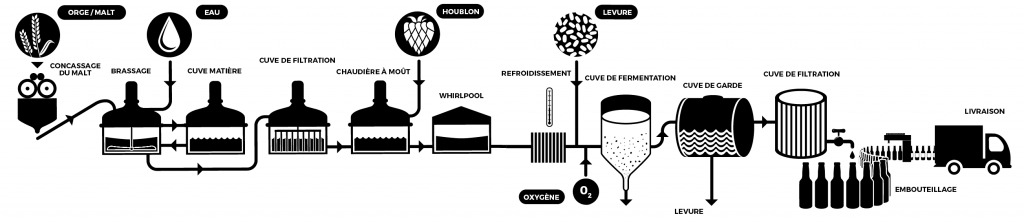

| Beer brewing process:

Malt is ground in the grain mill. The milled grains are transported with bags to mash kettle. In the mash tun the grist is mixed with brewing water from hot water tank(to form the mash) In the lauter tun the dissolved liquid extract (wort) is separated from the solids (spent grains) Brewing kettle is used for boiling. Whirlpooling is creating by circulating the wort. Cold wort is pumped through a hose from the heat exchanger to the fermentation cellar via the brew house pump. The wort ferments in the fermentation tank. The green beer matures in the serving tank. After the ageing process the beer can be served directly from this tank. |

Fermenter

| Detailed drawing: |

Specification of Stainless Steel Fermentation Tank Cooling Jacket Conical Fermenter:

Design pressure 3bar; working pressure 1.5bar

4 stainless steel legs with leveling footpads

Interior shell: 304 stainless steel, thickness 3mm

Exterior shell: 304 stainless steel, thickness 2mm

Interior and exterior finish bright polish to 0.4um, hygiene surface

60 degree cone bottom, other angles can be specified during the design process

Combined drain extensions and beer port in cone are standard

25% headspace, unless a different volume is requested

Top manhole or side manhole

Dual zone in sidewall and cone dimple cooling jacket with glycol inlet and outlet

Polyurethane insulation thickness 80mm for cooling jacket on side and bottom

Fully welded exterior shell

Non welding CIP arm and rotating 360 degree reach spray ball

Solenoid relief valve, pressure relief valve (safe valve) are standard

Pressure gauge

Temperature sensor well

Sanitary sample valve and port

All clamps and gaskets to attach all accessories

Tank complete with piping, fittings, sanitary valves and all parts.

Carbonation port is available for special request (stone not included)

Ladder hooks is available for special request

Dry hop ports and/or hop bag hooks in any fermenter of any size for special request

If you are would like to change, add, remove or modify any part of the tanks, we can accommodate that.

Our factory & company |

We have a wide range of products to choose from: small home brewing equipment, small and medium bar restaurant brewing equipment, large brewing plant fully automatic production line. Each product needs to be customized according to your specific needs and conditions. We will try our best to give our customers the most economical and perfect process.

Company advantages: |

Degong Equipment Technology Co., Ltd. specialize in designing, researching and manufacturing the brewery equipment, beer filling line and subsidiary equipment.

Our equipments have been CE ISO TUV UL certified. We are the only one who has got TUV certificate amongst all suppliers in north of China.

If you are interested,please feel free to contact me.