Description

What is a brewery?

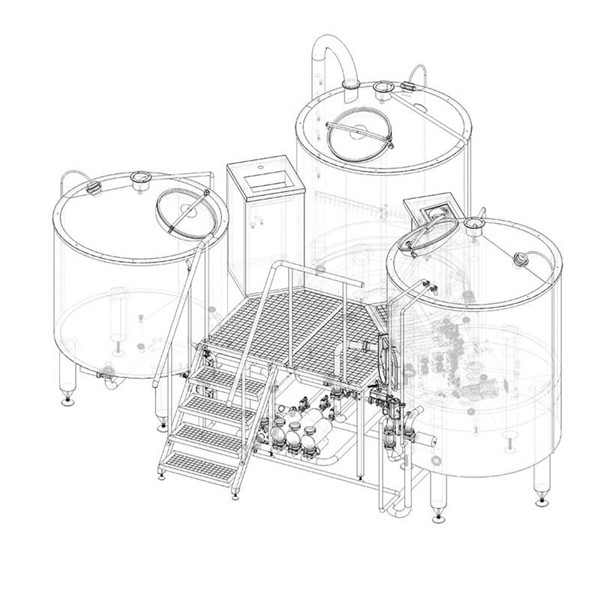

The brewery consists of several key brewing equipment. In the winemaker’s skilled palm, the malt paste bucket, the laurel bucket, the brewing kettle and the whirlpool transform the grain ground through a special grain mill into a sweet liquid called “wort”. The wort is then fermented and finished in a dedicated beer can called a fermentor and a special beer can.

The brewery is the heart and engine of the brewery and performs several key processes in the production of craft beer. The capacity, function and complexity of the brewery and other key beer equipment vary, but all breweries need to moisten the grain, separate the wort from the grain and boil the wort with a heat source. The three most common heating methods used in breweries are: steam, direct fire, electricity.

|

No. |

Name |

Components |

Specification |

|

1 |

Grain Milling System |

Rolling Miller |

Double roller |

|

Flexible Auger |

Stainless steel screw |

||

|

Silo |

SUS304 |

||

|

2 |

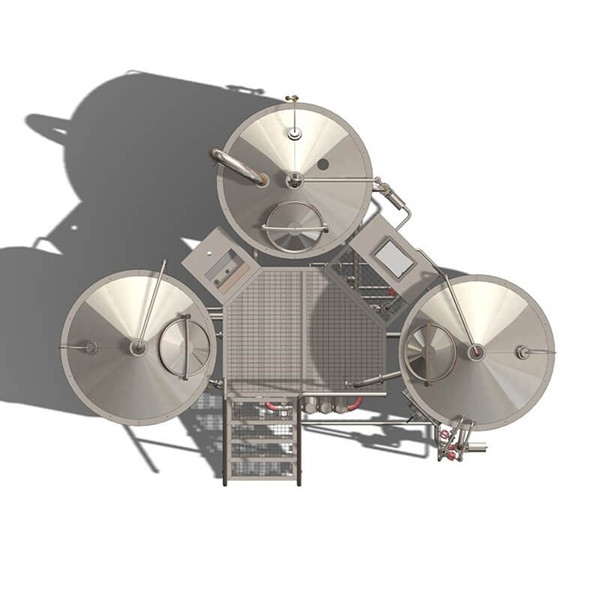

Brewhouse |

Mash tank |

Steam jacket on bottom and side |

|

Lauter tun |

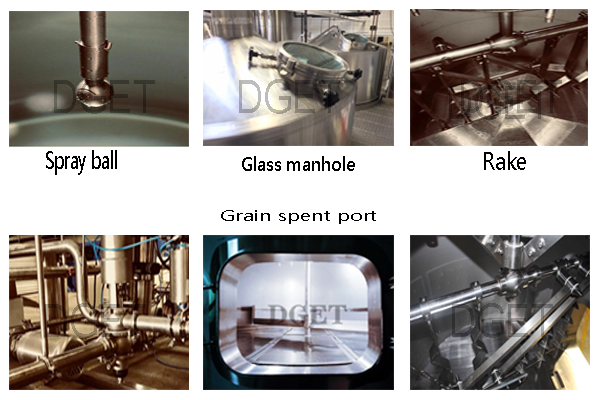

Grain rake with VFD |

||

|

Boiling Kettle |

Steam Jacket on bottom and side |

||

|

Whirlpool Tank |

Wort tangent inlet |

||

|

Hot water tank |

Steam jacket heating |

||

|

Heat exchanger |

SUS304 plate |

||

|

3 |

Fermentation tank |

Fermenter |

Glycol cooling jacket on cone and bottom Mechanical type safety valve |

|

4 |

Bright beer tank |

Bright beer tank |

Glycol cooling jacket on cone and bottom Mechanical type safety valve |

|

5 |

Cooling system |

Glycol Water Tank |

Insulated conical top and sloped bottom |

|

Refrigerating unit |

|

||

|

Circulate pump |

|

||

|

6 |

Control system |

Brewing and fermentation process Controlling |

PLC control with touch screen for special |

|

7 |

CIP |

Washing pump |

Electric heating element inside |

|

Sterilization Tank |

|

||

|

Alkali tank |

|

||

|

Control box |

|

||

|

8

|

Accessories |

T-Type thread

Changing diameter |

|

| Butterfly rubber seals | |||

| Insulation/heat

preservation material |

|||

| Saccharification

combination pipeline |

|||

| Pipeline & Valve VLV | |||

| Wort measuring meter | |||

| Rake | |||

| Food grade oxygen filling pipe | |||

| Refrigerant pipelines

Keep warm tube |

|||

| Mechanical type safety valve | |||

| An oil pressure gauge | |||

| Sampling valve | |||

| Temperature probe | |||

| Solenoid valve |

Features of brewhouse:(Brewery equipment)

– All tanks are made of food grade stainless steel 304.

– Adopting advanced world famous brand components in electric parts and operation parts.

– ABB motor for wort pump

– ABB/Siemens motor for raker and blender

– PLC automatic control method

– The structure of brewhouse: 2-vessel, 3-vessel or 4-vessel (Optional)

– Thickness: inner 3.0mm; out 2.0mm; jacket: 1.5mm

– Insulation: Polyurethane thickness: 100mm

– Working pressure: 1.5-2.0 bar Design pressure: 3.0 bar

– Inner surface treatment: welds grinded to Ra0.4µm without dead corner

– Outsourcing surface: weld polishing processing

– Heating method: steam; electric; direct fire (Optional)

– All welding are used argon gas protection welding. It will help to reduce the oxygenation and protect the joint.

Our welders has many years experience in welding and they adopt the most popular welding way–TIG welding.

– TC connected CIP arm with 360° coverage spraying ball

– Filter board gap is less than 0.7mm

– Dished top and conical bottom

– Stainless steel top mounted manhole and door

– 4pcs completely SUS304 heavy duty legs with leveling

– Two stage plate heat exchanger

– Mash & Lauter tun: Brewing & sparging water blending port, VFD rake, with wort grant, mash hydrator, etc

About us

–Our factory

–Contact information

If you are interested in our beer brewing equipment,please feel free to contact me.