Description

What is a beer mashing system of Beer Brew equipment?

Beer mashing system are comprised of several key pieces of home brewing system/commercial used brewing equipment. The whole brewhouse has four function,which is mash,lauter,boiling,whirlpool. In the skilled hand of the brewmaster, convert grain that has been milled through a specialtygrain mill, into sweet liquid called “wort”.Wort is subsequently fermented and finished in specialized beer tanks calledfermenters andbrite tanks.

Micro beer equipment home brewing system

Construction of beer mashing system

1.MASH/LAUTER TUN

Effective volume: vessel from 1BBL-80 BBL systems

Material: SS304

Finish: brushed external, polished internal less than 0.6um

Dished top, flat bottom, 4 legs with leveling feet

Bottom agitator, 2HP motor, 36RPM, VFD controls

Insulation 80mm rock wool

Raker with motor, gear box, VFD controlling

Grain spent blades

Grain Spent at side, 2-4 rpm

Removable false bottom, at same level with grain spent door

Sparging arm

Wort collecting pipes

Glass top manhole, spot light

Accessories include CIP, thermowell, condensing water outlet, sanitary valves & fittings

Heating Sources Available: Steam, Direct Fire, Electric (size matters)

2.BUFFER TANK

Connected to the outlet of lauter tun

Material S/S304

Effective volume 50L

Sight glass

Level with a false bottom

3.SIEMEN TOUCH SCREEN CONTROLS

Single step infusion brewing programs

Complex step mashing programming

Remote programming

German perfection

4.KETTLE/WHIRLPOOL TUN

Custom design

Effective volume: vessel from 1BBL-80 BBL systems

Finish: brushed external, polished internal less than 0.6um

Dished top, flat slope bottom, 4 legs with leveling feet

Working/designing temperature 100/150 degree

Insulation 80mm rock wool

Cladding steel 2mm S/S304

Wort collecting pipe

Glass top manhole

Accessories include CIP, thermowell, pressure relief valve, steam safety valve, condensing water outlet, sanitary valves & fittings

Heating Sources Available: Steam, Direct Fire, Electric (size matters)

5.HOP BACK

Material SS304

Mounted at the outlet of whirlpool

With pressure gage and valve & TC

6.MANIFOLD & C.I.P.

One of the most critical components to the craft. Bacteria management. Safe liquid looped emersion saves time and money. Custom designs to exceed the client’s demands.

7.HEAT EXCHANGER

Material:SS304

With EPDM gasket

2 station, 6 leads

15 m2 heating exchanging area

Inlet & outlet 2″ threaded

8.AERATION SYSTEM

Capacity: 1m3/h

Venturi tube

Check valve, pressure relief valve and pressure gauge

Titanium stick

Home brewing system mashing system

home brewing system frame

Micro brewery home brewing system valve&pipes

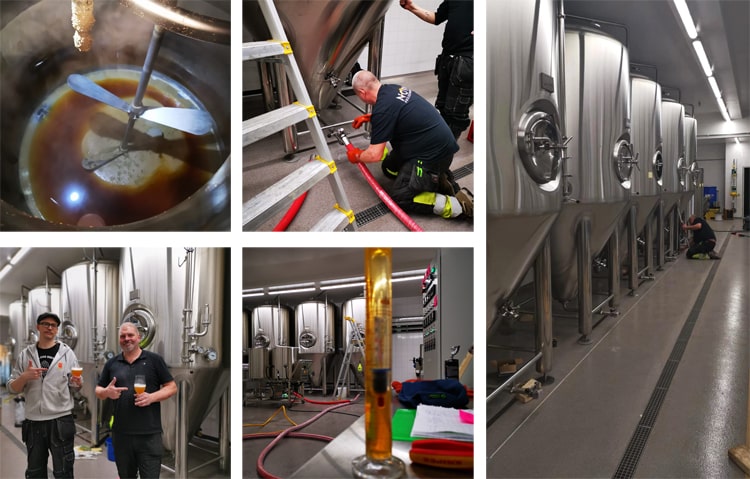

Dispatch engineer to install and debug equipment

Engineer install equipment in Sweden

Why choose us

1.Use the stainless steel plate made by the Chinese best-known stainless steel manufacturing enterprise, quality of steel plate is approved by Chinese testing organizations.

2. Use the Chinese famous brand YUANAN pump (ABB motor), use the wrold famous brand SIEMENS motor, ABB SIEMENS are both the world famous companies. Quality is guaranteed.

3. CIP tank with Insulation is more safe, which can prevent workers from being scalded.Take automatic temperature controlling system to control temperature, self powering off system prevents electric heating coil from dry heating.

4. Control system uses electric appliances of world famous brand, Schneider, Omron, Danfoss frequency converter ensure the stable runing of the whole system.

5. steam solenoid valve, solenoid valves for fermenters take first or second class brand of Chinese to ensure the stability of brewing and fermentation system

6. Warranty period 3 years