Description

Craft beer production line overview

Brewhouse system:

Mash/ lauter, kettle, whirlpool, hot water tank, the rake will have hydraulic lifting device.

Heating method: Electric heating, steam heating and gas heating.

Heat exchanger: Double or single stage plate heat exchanger.

Fermentation system:

Fermentation tank: SUS304, conical vertical tank ;

Test pressure:0.3Mpa, working pressure: 0.15Mpa;

Dimple type glycol cooling jacket,thickness is 1.5mm;

Top safety valve, Side manhole door, Rotary CIP spray balls, temperature sensor, Sample valve, Mechanical pressure valve, Pressure gauge, Glycol solenoid valves, Stainless steel legs with screw assembly to adjust legs height,Complete with associated valves and fittings.

Optional: bright beer tank, yeast adding tank etc.

Glycol cooling system:

Glycol wtaer tank, chiller, associated valves and fittings.

CIP System:

Sanitizer Tank, Caustic Tank. Associated valves and fittings etc.

PLC Control Cabinet

Power control, temperature display centrally, brewhouse control,

Fermentation tank with digital controller.

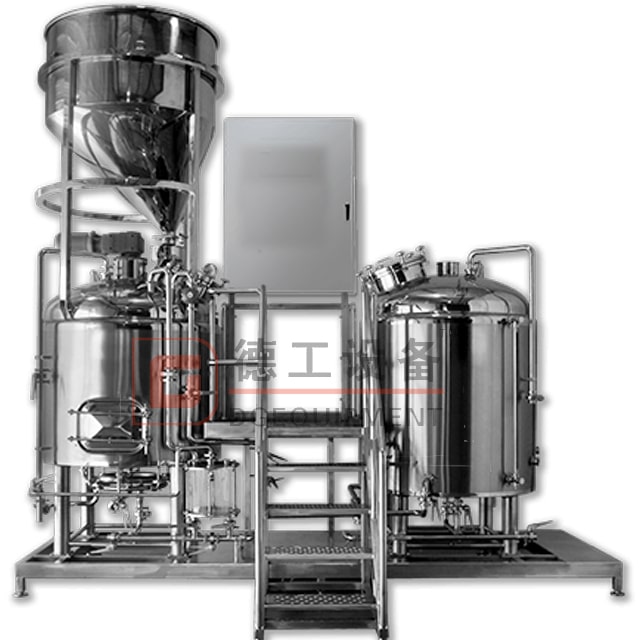

3-vessel brewhouse craft beer production line

3-vessel brewhouse craft beer production line

Craft beer production line brewhouse system feature

We offers flexible Brewhouse / Brew Kettle designs to ensure that optimal efficiency is achieved while including all requirements that a customer may have (such as spacing, tank distribution, etc.) Producing a high quality beer requires consistent brews and although experience plays a crucial rolein the process, the limiting factor is the quality of the Brewhouse being used. Having a high quality Brewhouse will ensure that you have the necessary tools to keep the same flavor profile with every batch!

Combination:(for 20BBL)

3-vessel:mash/lauter tun+boiling tun+whirlpool tun

mash tun+lauter tun+boiling/whirlpool tun

4-vessel:mash tun+lauter tun+boiling tun+whirlpool tun

3-vessel is more suitable for those with limited budget, while 4-vessel has high saccharification efficiency and high yield.

And heating method can be steam/electric/direct fire heating.

The three heating methods characteristics:

- Steam: Dimple plate jacket with inlet/outlet fittings for Steam heat transfer;

- Electric: Use electric heaters in jacket to heat the medium in the jacket;

- Direct fired: Use gas burner at bottom to heat tank directly.

If you choose steam heating,you need a boiler. There are gas/diesel/electric boiler. Customers can choose according to their needs.

raker&sight glass&spent grain hatch

raker&sight glass&spent grain hatch

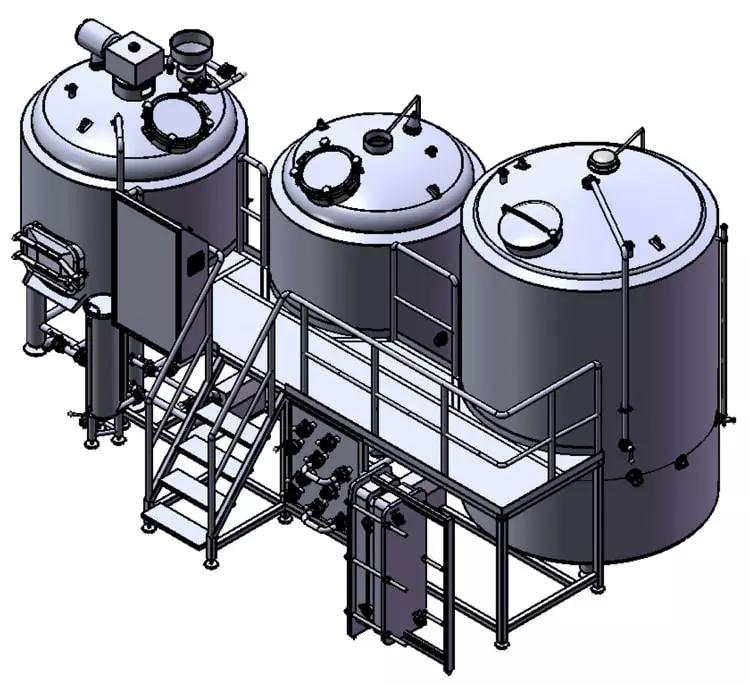

3D of 3-vessel brewhouse

Craft beer production line fermentation feature

- side manhole (standard).

- Level Indicator (standard) for inner tank.

- Vacuum/Pressure combined valve.

- Tank top fittings, pressure gauge.

- Optional: Pressure keeping valve with sight glass for controlling and monitoring fermenting process.

- Built in rotary spray ball within the inner tank for cleaning.

- Optional : Sanitary sampling valve, with the shortest connection on the tank, easily CIP cleanable.

- Manual ball valve for easy glycol changing over thus temperature control.

- Other customization possible upon request.

stainless steel fermentation tanks

stainless steel fermentation tanks

If you have interest, get in touch with me freely.