Description

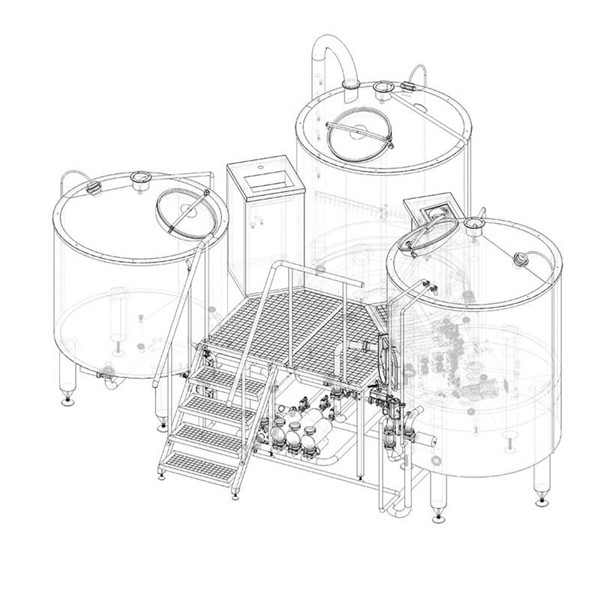

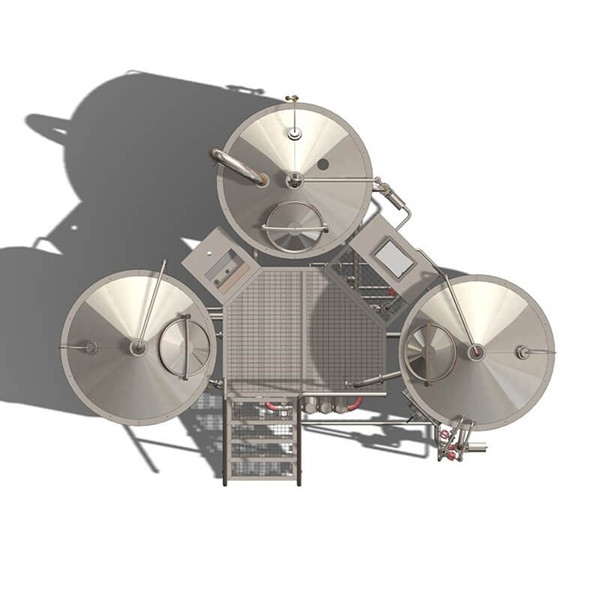

2500L stainless steel beer brewhouse equipment for sale

The beer brewing equipment is widely used in pub, laboratory, home. The configuration is flexible depending on different working efficiency.

Brewhouse combination is flexible according to your needs and daily work shift. In general, the brewhouse’s main tank: mash tun,lauter tun, kettle and whirlpool tank ,from one vessels to four vessels, heating way is electrical or steam heating or direct fire.

Fermenter quantity will depend on beer daily output and beer fermentation cycle.

Cooling system including glycol water tank, pump and chiller. The big cooling capacity used in heat exchanger, for cooling wort.

\

\

BREWHOUSE EQUIPMENT / MICRO BREWERY SYSTEM |

||

| Components | Specification | |

| Milling System | Miller | Double Roller |

| Heating System | Boiler (steam heating) | Electric or steam |

|

Brewhouse System |

Mash / Lauter tun | Heating jacket Material: SUS 304/316 or Red copper |

| Boiling / Whirlpool Tank | ||

| Heat-exchanger | Plate type | |

|

Fermentation System |

Fermentation Tank | Top manway/Side manway |

| Yeast Adding Tank | SUS304 Stainless Steel | |

|

Refrigerator System |

Refrigerator machine | With control system |

| Pump / valve | ||

| Ice water tank | Fluorine filling | |

|

CIP Cleaning System |

Acid Tank | SUS304 full welded |

| Alkali Tank | ||

| Pump | ||

| Control System | Control Cabinet | Semi-automatic |

Features of brewhouse equipment:

– All tanks are made of food grade stainless steel 304.

– Adopting advanced world famous brand components in electric parts and operation parts.

– ABB motor for wort pump

– ABB/Siemens motor for raker and blender

– PLC automatic control method

– The structure of brewhouse: 2-vessel, 3-vessel or 4-vessel (Optional)

– Thickness: inner 3.0mm; out 2.0mm; jacket: 1.5mm

– Insulation: Polyurethane thickness: 100mm

– Working pressure: 1.5-2.0 bar Design pressure: 3.0 bar

– Inner surface treatment: welds grinded to Ra0.4µm without dead corner

– Outsourcing surface: weld polishing processing

– Heating method: steam; electric; direct fire (Optional)

– All welding are used argon gas protection welding. It will help to reduce the oxygenation and protect the joint.

Our welders has many years experience in welding and they adopt the most popular welding way–TIG welding.

– TC connected CIP arm with 360° coverage spraying ball

– Filter board gap is less than 0.7mm

– Dished top and conical bottom

– Stainless steel top mounted manhole and door

– 4pcs completely SUS304 heavy duty legs with leveling

– Two stage plate heat exchanger

Contact information

If you are interested in our beer brewing equipment,please feel free to contact me.