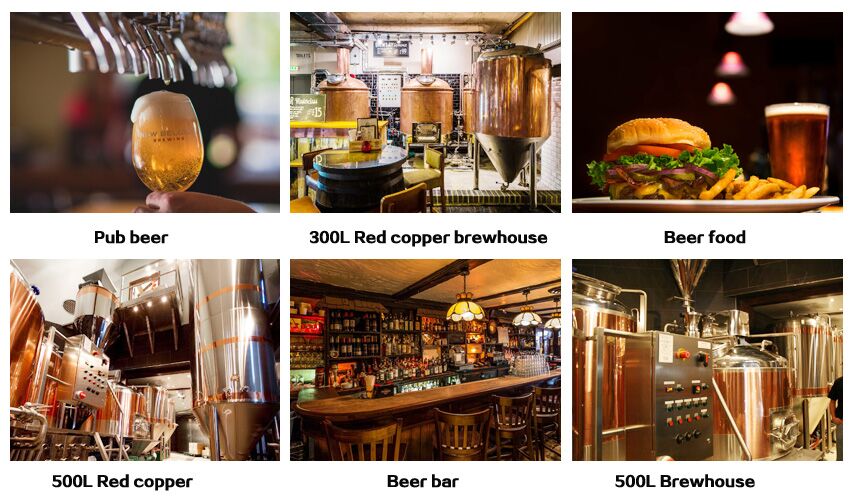

Description

The beer fermentation takes place in beer fermentation tank which come in various forms, from enormous cylindroconical vessels, through open stone vessels, to wooden vats. It is during this stage that sugars won from the malt are converted into alcohol and carbon dioxide, and the product can be called beer for the first time.Most breweries today use cylindroconical vessels, or CCVs, which have a conical bottom and a cylindrical top. The cone’s aperture is typically around 60°, an angle that will allow the yeast to flow towards the cone’s apex. Our fermenters are all customized, just tell me your requirements freely.

25BBL customized jacketed beer fermentation tank

- Jacketed beer fermentation tank

- Food grade sanitary stainless steel 304

- Design pressure: 3 bar Working pressure: 1.5-2 bar

- With 60 degree structure and 25% extra head space

- 4 stainless steel legs with leveling footpads

- Mirror polishing inside and 2B finish outside

- With L-type CIP hard pipes and spraying ball for cleaning tanks

- Dual cooling dimple jackets which is good for reducing the temperature

- Shadowless side manhole

- Rotating racking arm

- Thickness of inner: 3.0mm thickness of outer: 2.0mm thickness of jacket: 1.5mm

- Insulation: polyurethane thickness: 100mm

- Pressure gauge

- With all components included such as valves, release valve, mechanical regulation valve, sample valve, thermometer, temperature probe, solenoid valve, etc…

- All our fermenters are customized as requested. If you have your thoughts on the structure of fermenters, feel free to tell me.

- Certificated sanitary food grade SS304

- High quality valves & components

- Dual cooling areas which is easy to operate and good for saving energy

- At least 25 years using life

- Easy to maintain, operate. Saving time and labor

- All fermentation tanks should pass the tank leakage test before leaving our factory

- Carbonation stone port for special use

- With dry hopping at the top

- Fine welding seams treatment

- More economical and competitive

- Completely customizable as requested

- CE, ISO, TUV approval

- With tubular level meter for special use

- Novel structure and attractive appearance

- More humanized design

Contact me:

Email: [email protected]

WhatsApp/Tel: +86 15863177821

Skype: swift05