Description

The Nano Brewing equipment range from 100L to 1000L.And Nano Brewing equipment can be placed in: restaurants, pub, bars, hotels, tourist and shopping centers. Interpreter may be faced with polished brass, copper besides stainless steel. Also, the Nano Brewing equipment can be placed behind a glass partition that allows visitors to observe the process of making beer.

1.Normaly 2-vessel Brewhouse of nano brewing equipment

Mash –Kettle-Whirlpool | Lauter Tun | Hot water tank(Optional)

OR:Mash-Lauter|Kettle-Whirlpool| Hot water tank(Optional)

- VFD Control raker on Lauter tank

- VFD Control food grade SUS304 pump

- Plat heat exchanger(Single stage or two stage)

- Mashing control system

- Wort grant

- Hops filter

- Aeration device

- Pipes&Valves&Fittings

2.Fermentation system

Fermentation tank|Bright beer tank|Yeast adding tank

fermentation tank

Beer bright tank

Accessoreis on tank: Side manhole, Breathing valve, Cleaning ball, Dry hops adding port, Lifting lug, Cooling jacket, CIP Pipe, Temperature sensor, Sample valve, Mechanical regulation valve, Pressure gauge, Drain outlet, Racking arm, Cooling inlet, Cooling outlet, Legs, Base plate, Carbonation stone

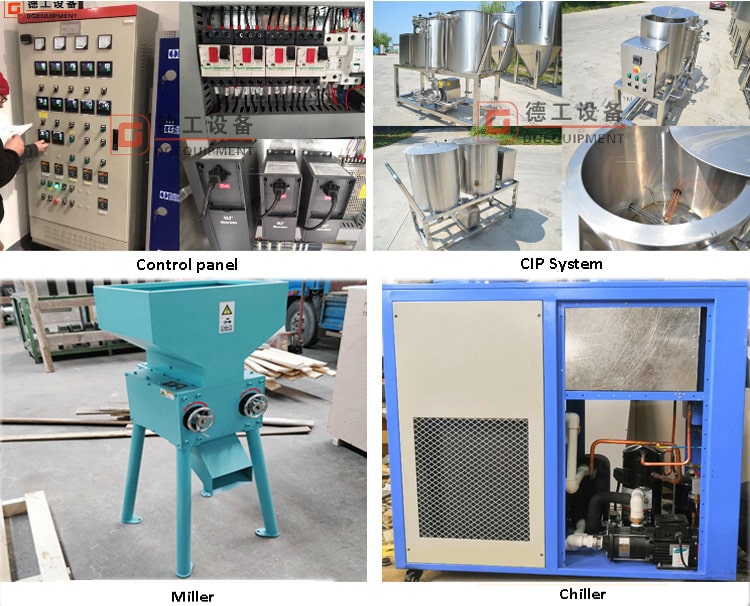

3.Cooling system

Glycol water tank|Cold water tankj|Chiller|Circulate pump

- The capacity of cooling system is depend on single stage or double stage plate heat exchanger,quantity and capacity of fermentation tank

4.Control system

Control the whole brewing progress,such as pump,motor,temperature,chiller………

- The component of the control panel is Schneider,Omron,Siemens,Danfoss brand.And the control panel is comply with UL certification

5.Other systems

- Complete malt-handling department: malt-mill, grist-auger, grist case, malt silos

- CIP-station in 2-vessel, 3-vessel or 4-vessel version

- Beer filters: Kieselguhr, plate or sterile cartridge beer filters

- Beer filling & packaging operation: bottling & packaging, kegging & oneway KEG filling equipment

- Dispensing tanks for beer drafting in beer pubs, bars and restaurants

If you have interest in DEGONG brewing equipment,welcome to contact me freely.