Description

The fermentation tank is the place where the cooled wort is finally fermented into beer. The fermentation tank is a double-layer stainless steel isobaric conical cylinder tanks with insulation. The substances entering the fermentation tank are wort, oxygen, and yeast (some brewers will add some dry hops to increase the aroma of the beer). After entering into fermentation tank,yeast performs aerobic respiration to multiply, then yeast performs aerobic respiration to produce CO2 and alcohol.

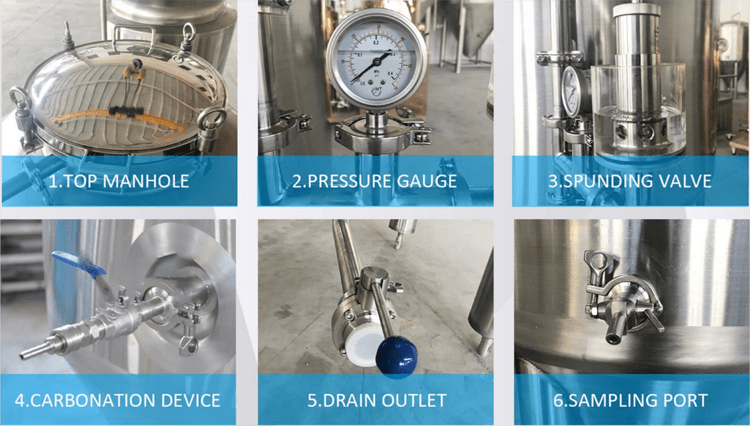

Beer fermentation tank features

Stainless steel, vertical, double-walled, insulated, 60 degree cone bottom, dished head, beer fermentation tank.Cylindrical and conical parts have independent glycol cooling zones controlled by temperature sensor.Part of dished head forms oval manhole, breathing valve set up at 1.5 bar and sanitation cleaning ball. There is a manhole, a hops hole on the top of the tank.A pressure gauge and a mechanical safe valve are connected on the L pipeline.There are also a sample valve,a temperature sensor,a thermometer in the cylinder of fermentation tank.conical part has bottom outlet yeast removal pipe and outlet for beer transfer to serving tanks.Tank is supported by 4 tube legs with fully articulating adjustable feet.

Take 20HL fermentation tank as a reference

N1.Side manhole N2.Breathing valve N3.Cleaning ball N4.Dry hops adding port N5.Lifting lug

N6.Cooling jacket N7.CIP Pipe N8.Temperature sensor N9.Sample valve N10.Mechanical regulation valve

N11.Pressure gauge N12.Drain outlet N13.Racking arm N14.Cooling inlet N15.Cooling outlet

N16.Legs N17.Base plate

Technical parameter of fermentation tank

- Inner Shell: 3mm, 304 Stainless Steel

- Outer Shell: 2mm,304 Stainless Steel

- Inner shell design pressure 29PSI(2bar), testing pressure 29PSI(2bar), designed to suit all types of craft breweries.

- Inner cooling jacket design pressure 29psi (2 bar).

- 25% headspace for fermenting process.

- Minimum 3 inch Thermal Polyurethane Insulation with both cone and shell coolant jackets.

- Chloride ion barrier paint on the out surface of the inner shell to prevent any potential corrosion to ensure longevity.

- Tank inner side is polished within 0.6µm sanitary finish.

- Tank outside is 2B stainless steel plate

- Shell and bottom cone cooling jacket for better temperature control.

- Pillow Plate on shell body and cone; Omega laser welded and inflated.

- Hook outside on the shell for ladders.

- Other customization possibly available upon request.

Degong brewing equipment can used in commercial brewery,brewpub or restaurant.

if you have interest,welcome to contact me freely