Description

SUS beer brewing equipment advantages:

- we support installation and debugging, technical guidance on site

- engineer will teach how to brewing and running the production line, test the beer’s quaity

- design drawing for free

- competitive and low price of raw material

- high quality of the beer equipment

- competitive price

- highly automatic or manual operation

- material: SS304 or red copper

SUS beer brewing equipment description:

1. Brewhouse: two vessels, three vessels, four vessels brewhouse

2. Heating medium: steam heating

3. Insulation material: polyurethane. Insulation thickness: 100mm

4. Mash tank; hydrator, mixer, steam heating jacket

5. Lauter tun: rake, agitator, false bottom, hydrator

6. Brewkettle, steam heating jacket, inner steam heating deivce

7. Whirlpool tun: whirlpool entry

SUS beer brewing equipment

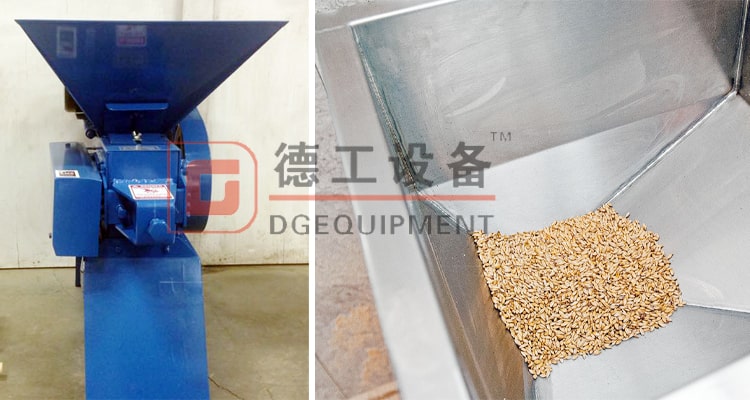

SUS beer brewing equipment mill system

Grain mill machine

Feature: high Efficiency, low noice, easy to operate, with high efficient, energy saving.

SUS beer brewing equipment mill machine

SUS beer brewing equipment mill machine

SUS beer brewing equipment mash system

There are several steps in the brewing process, which may include malting, mashing, lautering, boiling and whirlpool.

Normally, for 600L mash system, we recommend the available combinations, as follows:

Option1:mash /lauter tun + boiling/whirlpool tun(this is the most popular)

Option2:mash/boiling tun &lauter tun +whirlpool tun

Heating method:

You can choose steam/electric/direct fire heating.

Mash system parameter:

Interior Shell: SUS304/316 full welded; TH=3.0m

Exterior Shell:SUS304/316 full welded; TH=2.0m

100mm polyurethane for insulation

Acid washing and passivating the Interior finish to 0.4um

Speed adjustable grain rake (scraper blade for optional)

False Bottom/Filter

Steam condenser with spray nozzles

Completely stainless steel work platform

Two stages or single stage plate heat exchanger

Wort pump & hot water pump

Stainless steel 304/316 operation platform

2-vessel brewhouse system

1-the mash system is ruuning 2-spent grains hatch 3-raker 4-sight glass

SUS beer brewing equipment fermentation system

Fermentation is important in beer brewing. It plays an important role in the taste of beer. The number of fermenters is determined by production, but sometimes it depends on the style of the brewmaster.

Beer fermentater parameter

Insulation thickness: 100mm;

Inner tank thickness: 3.0mm; outer thickness:2.0mm

Racking Arm and discharge port with butterfly valve and fittings

dimple plate cooling jacket.

CIP arm and rotary spray ball

Release and breath valves

sample valve, mechanical pressure regulation valve

Pressure gauge & Thermometer & Sample valve

Dimple plate cooling jacket with glycol inlet and outlet

Four legs with brace and adjustable bolt

Interior of tank is mechanical polished, inner body polishing ratio 0.4μm. Out plate surface protection welding line Belt Sander Polished,welding: 100% Argon Arc welding

beer fermenter accessories

beer fermenter accessories