Description

| Customized beer brewing equipment |

A microbrewery or craft brewery is a brewery that produces a small amount of beer. The microbrewery process terms apply to breweries ,these are much smaller than large-scale corporate breweries and are independently owned. Such breweries are generally characterized by their emphasis on quality, flavor and brewing technique.

Brewing is the production of beer by steeping a starch source (commonly cereal grains) in water and fermenting the resulting sweet liquid with yeast.

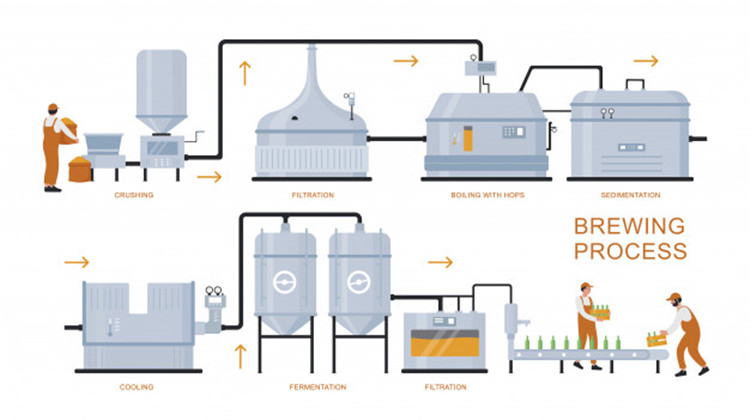

Steps in the microbrewery process include milling, mashing, lautering, boiling,whirlpooling, fermenting, conditioning and serving.

Beer brewing process

Grain miller(with double roller)

Milling is the process where making barley grain ready for brewing. this makes it easier to extract the sugars during mashing.

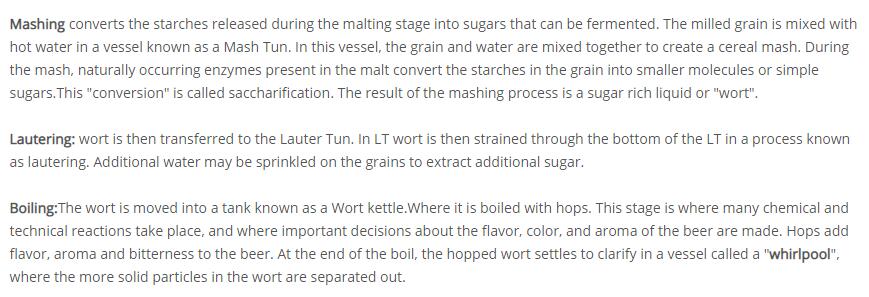

5BBL Brewhouse system for mashing,lautering,boiling and whirlpooling

Plate heat exchanger (city water and cold water);wort pump

Wort Cooling(Plate heat exchanger): After the whirlpool, Cooling wort via a heat exchanger to a temperature and adding yeast. It is very important to quickly cool the wort to a level where yeast can be added safely as yeast is unable to grow in high temperatures. After the wort goes through the heat exchanger, the cooled wort goes into a fermentation tank.

Fermentation takes place in fermentation vessels which come in various forms, from enormous cylindro-conical vessels.

After finishing of producing process the beer can be pumped into the Serving tanks (bright beer tanks).

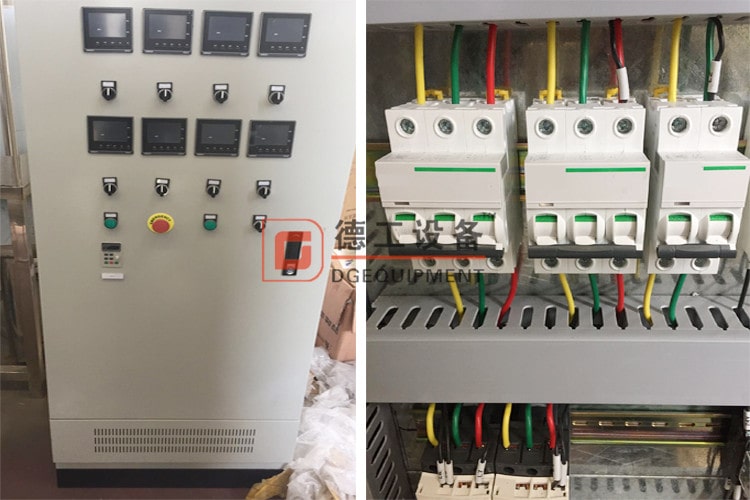

Semi-automatic control panel

Control system:– when the brewhouse equipped with the Automatic or semi automatic control system

Technological equipment: This includes malt mill, cooling units for the production of cold and ice water or glycol, plate heat exchangers, mobile CIP pump, hot water tank, tank for ice water or glycol, control panel, hoses and pipes, electrical wires…

Moveable cleaning cart

In short, if you want to know more beer brewing equipment related information and quotations, please feel free to contact me.

| Contact Alice today |

Talk to us about your requirements and we will design a system to work for you and your company.