Description

Our Industrial stainless steel brewery equipment is turnkey and automated ,consisting of mill system, mash system, fermentation system, cooling system, cleaning system (CIP), control system and accessories.The1000L brewery equipment can be used for both commercial used and private brewery.With this high-quality brewery equipment, you are able to produce outstanding full-bodied beers.

Quick Details

- Processing:Brewing Equipment

- Applicable Industries:Hotels, Food & Beverage Factory, Restaurant, Retail, Food Shop, Food & Beverage Shops

- Place of Origin:Shandong, China

- Brand Name:DEGONGET

- Volume Design:1000L

- Processing Types:Alcohol

- Voltage:380V or customized

- Power(W):15-70Kw depends on capacity

- Dimension(L*W*H):Depends

- Weight:Various in different models

- Certification:CE ,ISO,TUV

- Warranty:3 years

- After-sales Service Provided:Field installation, commissioning and training, Engineers available to service machinery overseas

- Equipment Material:SUS304 or Red Copper M2 for outer shell

- Thickness of Tanks:3mm for inner container/2mm for outer shell

- Color Availabl:Mirror SUS, Luxury red copper

- Heating:Electric/steam/direct fire heating

- Heat Insulation:Polyurethane with Thickness 80mm-100mm

- Inner Polishing Precision:0.4 Micrometer

Malt miller:

- 300-500kg/h

- Doubel roller

- Nosie: 45db or so

malt miller

malt miller

Brewhouse system:

- 1000L Mash/Lauter tun

- 1000l Kettle/whirlpool tun

- Steam heating method

- 1000L hot water tank

- Tubular galss level indicator

- Tangential wort inlet

- Side mounted grain outdoor with grain chute

- Laser cutting V-wire False Bottom

- Heating exchanger: 10 square meters

- Wort pump: ABB motor, VFD control

- Wort aeration device

- Yeast adding tank: 30L

- Seamless food grade stainless steel 304 pipes

- Working platform

3D-Modle of 4-vessel brewhouse equipment

grain outdoor and Tri-clamp Connection

working platform and sieve plate of the mash/lauter tank

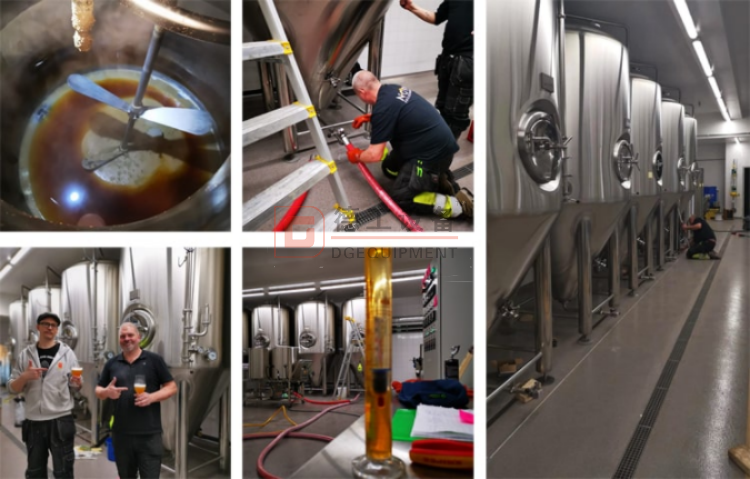

Fermentation system:

- Material Inner (SUS304) thickness: 3.0mm; Outer (SUS304) thickness: 2.0mm; External-Jacket(SUS304) thickness: 1.5mm;

- Equipment with : cone 60°resist compression design,dripping

- 100% TIG welding with pure argon gas shield

- Interior Finish: Sanitary 2B finish, Pickled and Passivity; (8K Mirror finish optional)

- Exterior Finish: Oil brushed finish (2B, 8K Mirror finish optional)

- Interior full polished to 0.2~0.4 μm without dead corner

- Insulated with high density Polyurethane foam 100mm

- Glycol Jacket: Dimpled plate on cone and side

- Stringent Jacket leakage test by water and pressured gas

- Sanitary side mounted manway with pressured door

- TC connected CIP arm with 360° coverage spraying ball

- CO2 blow-off arm with butterfly valve

- Full sanitary metallic sealed sampling valve

- Mechanical safe valve PVRV 2 bar on top

- Hydraulic shock pressure gauge on CIP arm

- Rotating racking arm and port on cone with butterfly valve

- Tri-clamp discharge arm with butterfly valve

- Thermowell for high accuracy temperature sensor

- 4 pcs completely SUS304 heavy duty legs with leveling pad and legs support

- Dry hopping port 4” TC with solid end cap

fermentation tank unit and details

CIP system:

- 100L alkali tank with electric coils assembled inside 100L acid tank control box Trolley

Cooling system:

- 7HP chiller, Power: 5.25KW, Cooling capacity: 16268Kcal, Refrigerant: Freon R404A, Copeland compressor

- 1500L glycol water tank

- Glycol water circulation pump, VFD control

- PPR pipes

cold water tank with side manhole

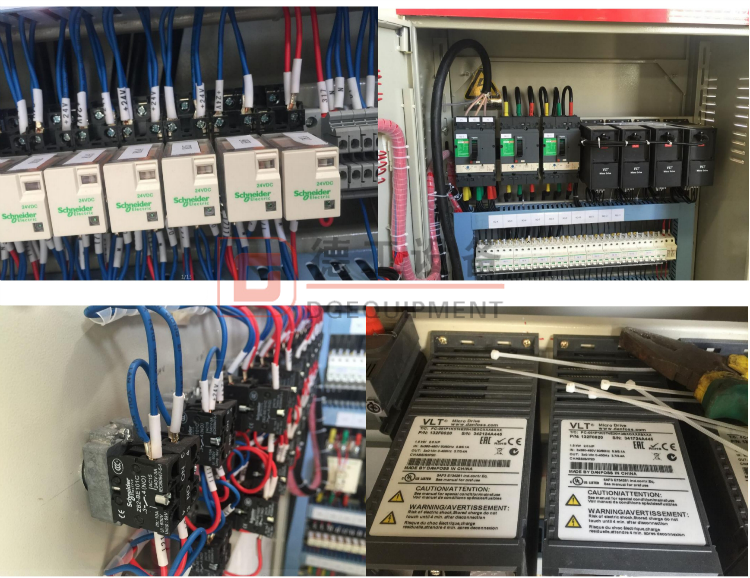

Control system:

- Semi automatic control system or PLC fully automatic control system if requested

- Siemens/Schneider/Omron components

- PC or mobile remote control if requested

- Individual control system for brewhouse system and fermentation system

control sysytem/details of brewery equipment

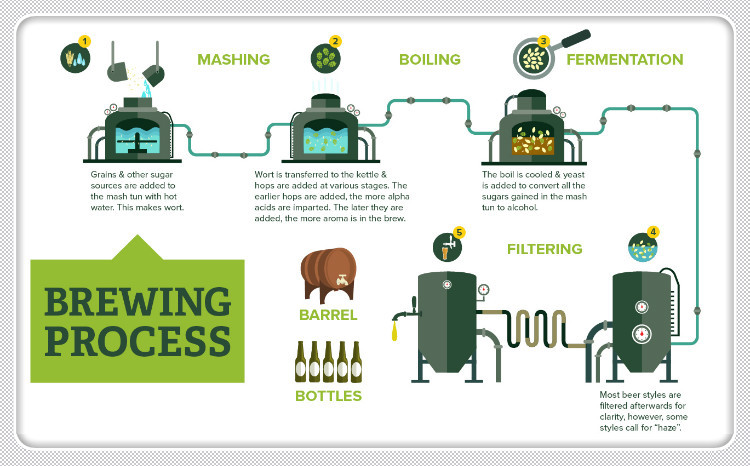

Brewing process

brewing process from mashing to bottling

Packing and Delivery

- Packaging Details: standard wooden package

- Package Type : As usual, we adopt wooden case as package type. It’s suitable for long-distance transport. According to customers’ special demand, we could adopt sheet iron case and so on.

standard wooden packing and delivery

Our Service

- Free consultation service before, during, and after sales;

- Project planning and design services;

- Free debugging instruction of equipment until everything is functional;

- Management of equipment’ s long distance shipping from seller’s factory to named port or station by buyer;

- Training of equipment maintenance and operating personally;

- New production techniques;

- Provide 36 months complete warrantee for main parts and life-time maintenance service;The seller is responsible for the nature damage of the machinery in the warranty period except for man-made damage. All spare parts and wearing parts are attached with the machinery for free

Our certificate

With the high standard of brewery equipment both in row materials and manufactures, Degong have passed 4 international certification: ISO9001,ISO14001,SGS and CE

The certificates of Degong

Customer visiting

we welcome customers over the world to visit our factory

we welcome customers over the world to visit our factory

About us

DEGONG is a large manufacturer of beer brewing equipment, which the headquarter is located in China. Dedicate to beer equipment, beer fermentation equipment, beer bottling machine, beer keg filling machine, beer filter machine, wine production equipment, wine fermentation tank, pasteurizing equipment, water treatment equipment, steam boiler and so on. Provide the total solution to customer from designing, consulting, product to project implementation to fit each brewer’s individual needs.

Contact us