Description

300L Complete Microbrewery equipment is very popular for small brewpub,restaurant….Some customers have their own bars or restaurants, and they choose 300L Complete MicroBrewery to brew craft beer to attract more customers; Some customers are brewing enthusiasts,and they choose 300L complete microbrewery equipment to brew beer according to their preferences; And some large industrial breweries choose 300L equipment for experiments, before mass production, they choose 300L small equipment to adjust the beer formula to determine the final brewing formula

| Production introduction |

300L beer brewhouse-Complete microbrewery

|

1.Mash tank:heated vessel for the mixing of the squeezed malt in water and boiling of malt mash |

2.Lauter tank:the tank with special sieve for the filtration of malt mash (separation of liquid wort from solid parts of malt)

|

|

3. Boiling tank : the heated vessel for the boiling of wort with hops. This function may be integrated into the malt mash boiling tank

|

4.Whirlpool tank – tank equipped with a tangential inlet for centrifugal separation solid rests of hops from wort – this vessel may be situated also as an external device |

|

5.Supporting equipment Motors with agitators/Raker for mixing and cutting of malt mash False bottom in lauter tank with gap of 0.7um a hot water tank and a cold water are usually needed Pump,pipes,platform

|

6.Technical parameter Be made of food sanitary stainless steel 304 Inner surface treatment: welds grinded to Ra 0.4µm without dead corner. 100% TIG welding with pure argon gas shield Insulation: Polyurethane-thickness 80 mm. Temperature way:Double metal thermometer CIP rotary spray device Thermo well for high accuracy temperature sensor |

REMARK:For 300L Micro brewery equipment,combined mash/latuer tank+boiling/whirlpool tank is the best choice

300L/600L Fermentation tank–Complete microbrewery

|

Main Features 100%TIG Inner Shell: 3mm, 304 Stainless Steel Outer Shell: 2mm,304 Stainless Steel Design pressure 3bar, testing pressure 2bar 25% headspace for fermenting process. Equipment with : cone 60°resist compression design 80mm Thermal Polyurethane Insulation with both cone and shell coolant jackets. Tank inner side is polished within 0.6µm sanitary finish. Tank outside is 2B stainless steel plate. Shell and bottom cone cooling jacket for better |

Component on tank 1.Dimple cooling jacket 2.Breathing valve on top 3.Hops adding port on top 4.CIP arm 5.TC connected CIP arm with 360° coverage spraying ball 6.Pressure relief valve PVRV 2 bar on CIP arm 7.Full sanitary metallic sealed sampling valve 8.Hydraulic shock pressure gauge on CIP arm 9.Thermowell for high accuracy temperature sensor 10.Rotating racking arm 11.Carbonation stone |

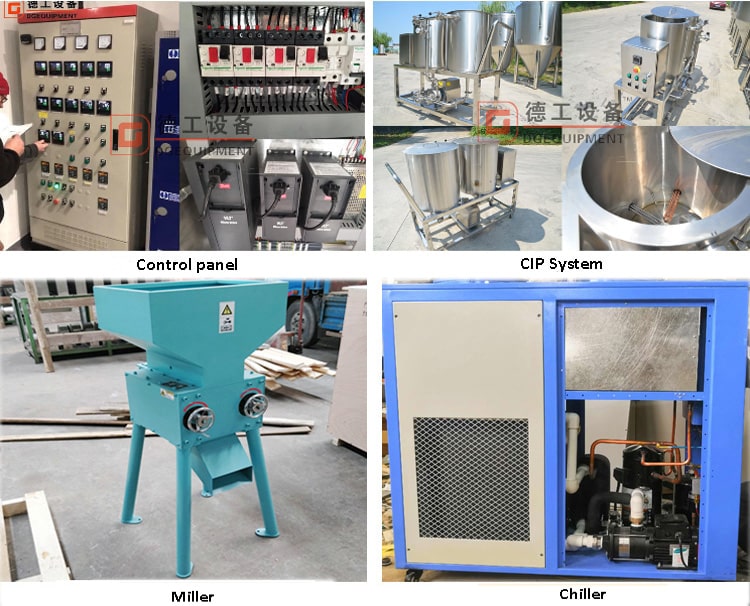

Other necessory system-Complete microbrewery

|

Miller system:Breaker Roll Type; Adjustable mill degree; |

Cooling system:Glycol water tank; Cold water tank; Chiller; Circulation pump |

|

CIP system:Alkali tank; sterilization tank; pump |

Control system:Siemens,Omron,Schneider,Danfoss component |

| Company information |

Weather you want to brew craft beer or brew commercial/industrial beer,weather you want to start a new beer brewery project or expand your brewing scale.No matter what you want to brew lager or ale, stout beer or light beer,barley beer or wheat beer,fruit beer or corn beer,low concentration beer or high concentration beer….DEGONG brewing equipment always can meet

If you have interest in beer brewing,welcome to contact me freely