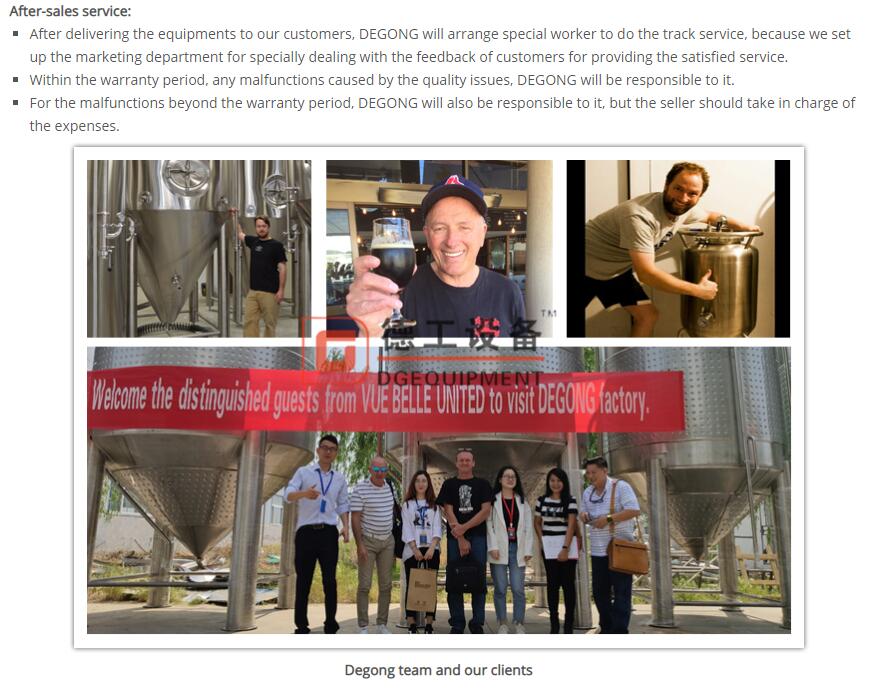

Description

Beer has as long a history as human civilization. It first appeared in human life before other alcoholic drinks. After the technology of brewing beer spread to Europe, it developed rapidly. Through the continuous improvement and development of europeans, beer has become one of the most popular drinks in the world. When we say beer, of course, beer equipment is essential.

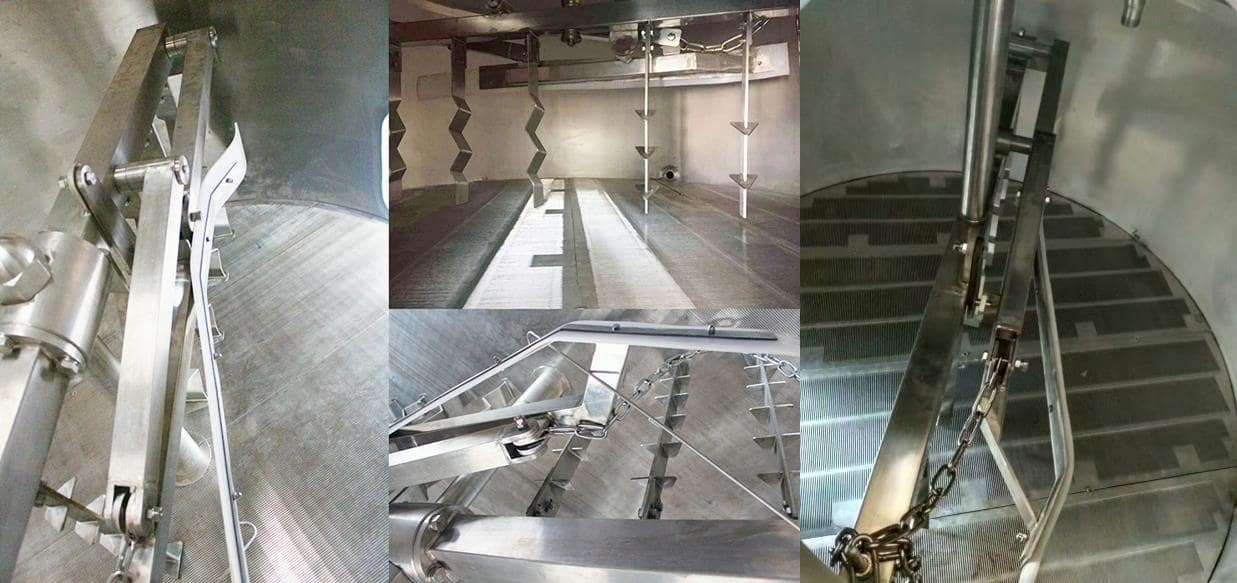

Craft kettle brewing equipment can be designed according to the requirements of different brewers.The whole set Craft kettle brewing equipment includes miller, mash system, fermentation system, cooling system, control system, cleaning system, filtration system, sterilizer, filling line (bottle, barrel, can), packaging.

The two most important steps in beer production are beer mashing and fermentation.So let’s focus on the equipment needed for these two parts.

Beer mashing is one of the most important processes in the preparation of wort. The brewhouse required is mash tank, lauter tank, boiling tank and whirlpool tank. Of course, in order to improve mashing efficiency, most customers will choose a hot water tank to prepare hot water in advance,which can save time.

Craft kettle brewing equipment

Normal configuration of mashing system

Heating method of brewhouse |

|

| Steam heating | More efficiency,suitable for 500L and more than 500L brewhouse |

| Electric heating | Save cost,suitable for brewhouse under 500L |

| Direct fire heating | If electric and steam is not convenient for the brewery,so we can choose direct fire heating |

Main technical parameter |

|

| Material | Stainless steel 304,Inner thickness:3mm,Outer thickness:2.0mm,Jacket thickness:2.0mm |

|

Inner surface treatment: |

welds grinded to Ra 0.4µm without dead corner. |

|

Insulation |

Polyurethane-thickness 100 mm |

|

Jacket Pressure |

design pressure 0.3 MPa, working pressure <0.2 MPa.(If steam heating) |

| Cleaning | Top mounted 360° coverage CIP spraying ball and port |

|

Other features |

Hopper and grist hydrato US made top mounted VFD controlled mixing agitator,raker and pump Top many with tempered sight glass Interior LED lights Side man way for spent grain removal process Crossbar support system for false bottom Automactic spent grain removable system Tangential whirlpool port |

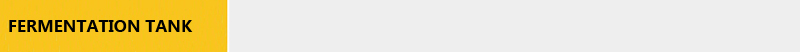

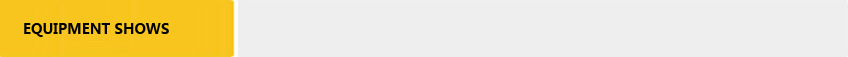

Fermentation tanks, or more commonly fermenters, are key components in beer brewing. Fermenters are specialized tanks designed to precisely control temperature and maintain the optimal conditions for fermentation, which occurs once the wort has been transferred from the brewhouse to the fermenter; a conical-bottom design is highly recommended for fermenters allowing for easier yeast harvesting.

Fermentation tank

Beer fermentation tank technical parameter |

|

100% food-grade 304 and 316 stainless steel |

|

All fermenters are rated to 0.15MPa (1.5 bar) operating pressure |

|

Two-zone glycol jacketing,and 60-degree conical cone |

|

Top-mount manway (Meanwhile optional side-mount configurations available) |

|

Complete thermal insulation of side walls and cones |

|

All insulation is fire retardant fiber cloth (not foam) |

|

All welds are blended and finished to a sanitary food-grade finish |

|

Every fermenter is equipped with: racking arm pressure relief valve blow-off/ clean-in-place (CIP) tube CIP spray ball sample valve butterfly valves TC clamps, gaskets and clamps 90-degree elbows optional rupture disc assemblies available |

Wooden packing or Frame Packing to avoid demaging during transportation