Description

7BBL brewing equipment

The beer brewery is designed just for the American and Canada market, with grist hydrator, grant, skid mounted platform, two pumps, multi-positioned butterfly valves, which is our high standard for North American market. We are specialized in manufacturing different types of industrial breweries and microbreweries to different clients in the world. The full line products including milling, mashing, fermentation, cooling, filtration, filling and other related processes. We focus on each brewing system to stringent testing procedures before publishing them in the market.

7BBL high quality Brewhouse system

1. Products: Pub Brewing equipment

2. Capacity: 7BBL

3. Semi-auto Control

4. Material: Sanitary Stainless Steel SUS304/SS316/red copper

5. Function: Beer Brewery

6. Over 10years powerful factory

7. Customized service

8. Home Pub Resturant Hotel Use

7BBL Brewhouse combination

7bbl Mash/lauter tun, 7bbl kettle/whirlpool tun, 8m2 plate heat exchanger

Detailed configuration:

Mash/lauter tun:

Material: SUS 304;

Inner TH=:3.0mm; External TH=2.0mm;

Insulation layer: PU-thickness: 80mm;

Top manhole: round glass manhole 350mm;

Lauter tank equipped with plow knife (raker knife with scraping plate); Raker motor;

Top manhole: round glass manhole; Side grain outdoor with grain chute;

Easy-clean and detachable Sparging

Laser cutting T-wires false bottom (filter);

Filter way: Suction filtration by speed controlled pump;

Flat base, with wort collection tube and under flush system

Equipped with balance tank and grain out dustpan;

360° coverage CIP spraying ball;

Temperature measurement way: PT100

4 completely SUS304 heavy duty legs with leveling pads

Steam jacketed heating 2 zone

Copper construction can be available

Kettle/whirlpool tank:

Material: SUS 304;

Inner TH=:3.0mm; External TH=2.0mm;

Insulation layer: PU-thickness : 80mm;

Top manhole: round glass manhole 350mm;

360° coverage CIP spraying ball;

Temperature measurement way: PT100

4 completely SUS304 heavy duty legs with leveling pads

Heating way: Steam heating;

Steam vent by steam condenser with spray nozzles

Sanitary leveling sight glass at the back of kettle;

Tangential whirlpool inlet

Platform: Normal standard

Pumps ABB

Fermenting vesselsbrewing equipment

7 BBL Jacketed Fermenter- Stainless Steel

Total Volume: with 25% head space

Inner shell: SUS 304 T3mm;

Exterior shell: SUS 304 T2mm;

Dimple cooling Jacket: SUS 304 T1.5mm

Insulation: PU 80-100mm

Other Configurations

Top:Dome Top, with rotating CIP ball TC

Bottom:Conical 60 Degree with Drainage Valve

Jackets:Both on Bottom and Cylinder Parts

CIP:CIP Arm with Rotating ball, Butterfly valve

Valves:Safety/Vacuum Valve, Sample Valve

Outlet:Rotation Racking Arm SMS76*32TC Valve

Temp.:Thermometer and PT-100

Testing:Test:0.3Mpa, Working: 0.15-0.2Mpa

Pressure:Bung Apparatus with Pressure Gauge

Polishing:0.4-0.6μm/ or Mirror polishing

Legs:4 legs with adjustable Bolts

Cooling:Cooling ports(cooling medium inlet and outlet)

Parts:With gaskets, Cooling pipe fittings

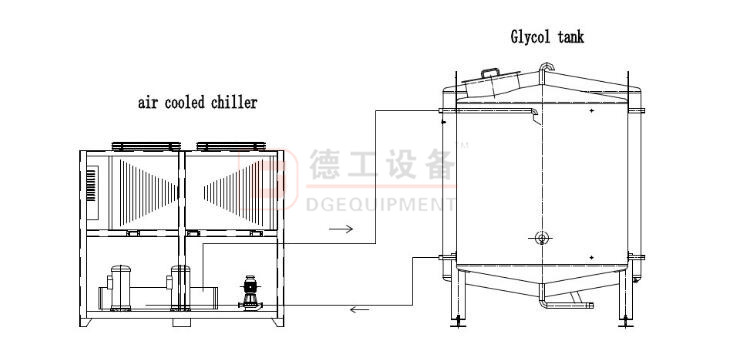

Cooling system(chiller and Glycol tank)

Technical Description:

■ This system can meet beer mashing requrements, inoulding malt milling, mashing, fermenting, cooling, distribution and so on.

■ All tonks were mode by SUS304, in accordance with the standard of food hygiene and safety stoandards. Steam heoting.

■ The tonk is equipped with variable frequency mixer which con ochieve the change of ootating speed from 0 to 50r/min and meet the requirements of

rototing speed for mashing mixing and fltration tank mixing.

■ Automotic control or semi-automotic control wil design according with customer requirements.

■ Input and output of material and sel-circulation are connedted by sanitation pump and hose.

■ Connedion type of pipelines for equipments is quick assembly which is convenient for deaning, maintenance and epair during produdion.

■ Resonable design, delicoted process, nice oppearance, durable service, easy for operotion, repair and mointenance

Contact us

Ready to Get Started Building Your Dream brewery?

Contact DEGONG Alice Today!