Description

| Artisanal Brewery Plant Equipment 1000L |

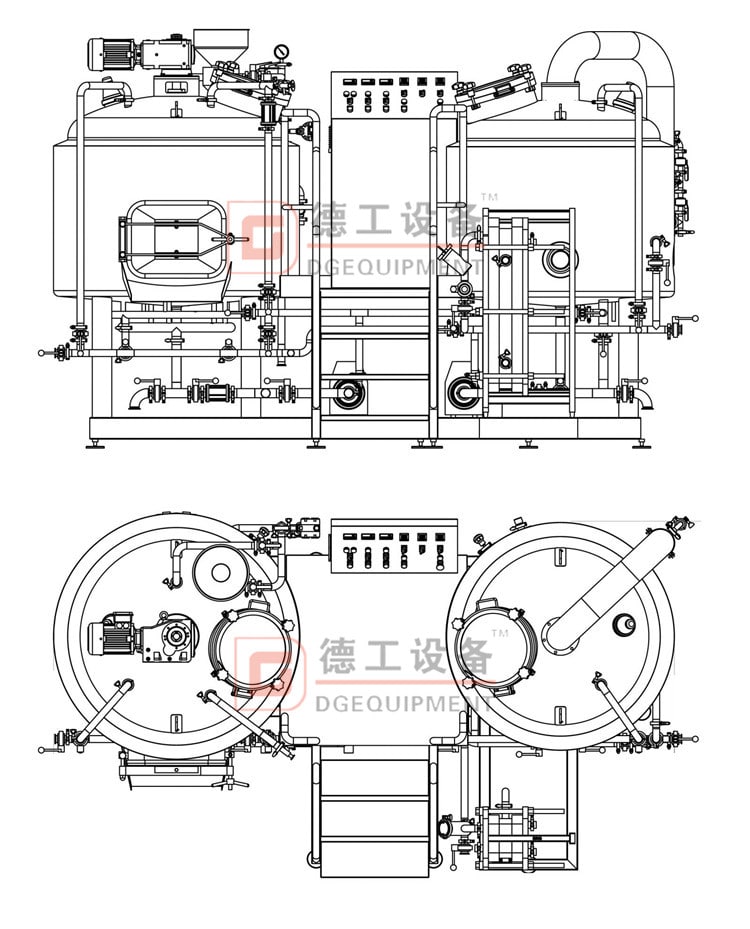

Two-vessel Artisanal Brewery Plant

Brewery Plant list:

| NO. | Equipments Request | Components |

| 01 | Mashing System | Mash/Lauter Tank |

| Wort pumps | ||

| Boiling/Whirlpool Tank | ||

| Hot water tank | ||

| Other accessories are available: 1. Stiring Device; 2. Butterfly Valve DN32;

3. Malt Miller; 4. Sugar Meter; |

||

| 02 | Fermenting system | Cylindrical-conical fermentation tank,including necessary fitting:pressure gauge,buning valve,pressure vaccum relief valve,and more |

| 03 | Cooling system | Chiller with compressor |

| 04 | Capacity | 1000L/Day |

| 05 | Trade Term | EXW, FOB, CIF |

| 06 | Payment Term | T/T in advance |

| 07 | Packing Size(L*W*H) | Packed in 40HQ conatiners |

Fermentation tanks installed Artisanal Beer Brewing Equipment

We provide Components with quality Artisanal Brewery Plant

(1) All product leading parts in stainless steel 304 and food grade;

(2) Complete per-fabricated unit, grinded surface, well welded, prolong the service life of equipment;

(3) Perfect design, top quality accessories, to minimize the equipment’s failure rate.

Compact brewhouse

Standard and custom-made equipment for small and medium-size breweries;

all-in-one-designs / compact designs / combi tanks and multifunctional tanks in different combinations combined in a single system / individually designed tanks;

equipped with an effective cooling and heating system, insulated

vessels with thermal bottom and jacket;

completely piped and wired,

with an integrated pump system,

platform for combining the vessels in a compact unit,

with installed CIP system.

Adding hops in hot water tank

Sight glass,top manway,raker;spent grains door

Top view of Artisanal Brewery Plant

Beer brew equipment is typically smaller than independent micro brewery equipment. We offer medium beer brew equipment with the productivity of 500L (5 hl) to 5000L (50hl) per brew. The red copper brewhouse is also the preferred choice for most brew pub. The fermentation tanks for brew pub is usually not large but with more numbers for serving more beer flavors on taps. A typical brewing process for brew includes milling, mashing, fermentation, maturing, cooling, controlling, cleaning, filling and beer serving.

| Contact Alice today |

Talk to us about your requirements and we will design a system to work for you and your company. wlcome to consult brewery to get a perfect quotation.