Description

1000L affordable beer brewery equiopment overview

| Name |

Composition |

Technical parameter |

| Mill system | grain mill machine |

Double roller Carbon steel spray paint/Stainless steel Power:1.5Kw |

|

Mash system |

mash/boiling tun |

Material:SUS316L/SUS304/copper Interior Shell: 2B/mirror plate; TH=3mm Dimple, coil jacketed for steam heating,electric ABB stirring motor 80mm rock wool for insulation Round glass manhole, dish head,with temperature sensor,cleaning tube, standard Washing ball |

| lauter/whirlpool tun |

Material:SUS316L/ SUS304/copper Interior Shell: 2B/mirror plate; TH=3mm 80mm rock wool for insulation Lauter tun with round glass manhole,side mounted grain outdoor with spent grain chute,sampling valve,sight glass Lauter plate: milling Racking device,positive turn cultivating spent grain,reverse discharging spent grain Tangential whirlpool inlet With cleaning tube, with standard washing ball,cleaning pipelin |

|

| Hot water tank |

Material:SUS316L, SUS304,copper Interior Shell: 2B/mirror plate; TH=3mm 80mm rock wool for insulation Top dish head, bottom conical head, round glass manhole Dimple, coil jacketed for steam heating,electric heating tube, combustion chamber With a cleaning tube, with a standard wash ball, cleaning pipeline ISO32, overflow port,temperature sensor |

|

| Plate heat exchanger |

SUS304,Two stage cooling |

|

|

Yeast adding tank |

With valve, sight glass, pipe fittings, hand-held thermometer, display instrument, etc |

|

|

wort pump hot water pump |

China top brand, Sanitary SUS304 |

|

| Heating method | steam heating, electric heating, direct fire heating | |

| Fermentation system | fermentation tank |

Material:SUS316L /SUS304 Interior Shell: 2B/mirror plate; TH=3mm 80 mm PU for insulation Dish head,cylinder,60 degree cone bottom(adjustable) Top or side manhole, With electromagnetic valve or mechanical pressure regulating valve,sample valve,temperature sensor, adjustable leg,Rotating Option:Dry hop mouth,CO2 filling device With titanium |

| bright beer tank |

Material:SUS316L or SUS304 Interior Shell: 2B/mirror plate; TH=3mm 80 mm PU for insulation Dish head /bottom,cylinder Top or side manway With electromagnetic valve or mechanical pressure |

|

| Cooling system |

Chiller qlycol water tank pump |

Insulated conical top and sloped bottom Sanitary SUS304, VFD control |

| Control system |

mashing and fermentation process Controlling |

Panel instrument digital PLC control with touch screen for special |

| CIP system |

Acid Tank Alkali Tank CIP Pump |

stainless steel 304 Flow:3T Lift:24 |

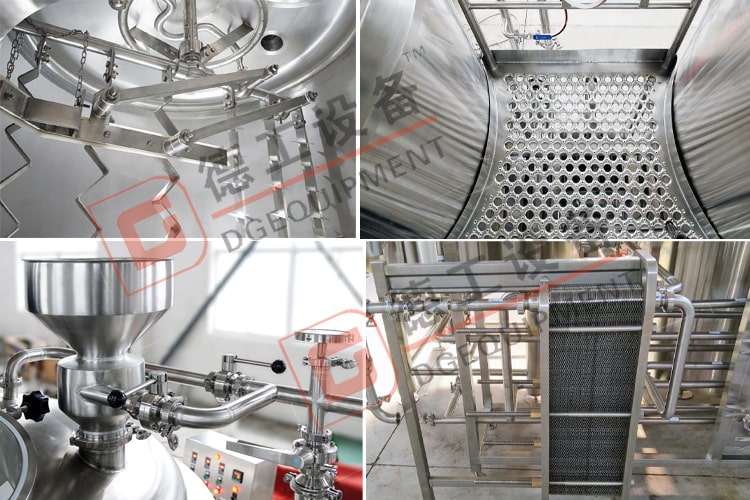

Affordable beer equipment mash system details

1-mash tun

The use of highly efficient miller jacket heat techology, the application of scientific principles og steam turbulence to achieve maximum heat transfer, energy-saving effects, taking fullly automated temperature control techology, ensure the heating,the heating accuracy at the stage of the mash process.

With ABB VFD motor, false bottom, spary cleaning ball, sparing ring, raker, manhole

2-lauter tun

The use of advanced scientific farming raker structure and hydraulic automatic take-off and landing system technology to ensure the uniform double slot, the smooth groove and aslo the improved lautering speed and production efficiency. Maintain the transparency of the wort and a good juice yield.

With

raker and wort pump with VFD ABB motor to adjust the speed.

laser cutting sieve plate with the gap 0.7mm and thickness is 4mm

Spent grain hatch, sight glass, top glass manhole

3-Boiling tun

In application of advanced boiling to improve the boiling intensity, rapid separation of boiled wort.

4-Whirlpool tun

To design according to the best program of rotating separation, enlarge the proportion of the height abd diameter, reduce speed to achieve the best separation.

raker& operation platform& hydrator& plate heat exchanger

Affordable beer equipment brewhouse pipe details

Affordable beer equipment brewhouse pipe details

Affordable beer equipment fermentation tank details

Affordable beer equipment fermentation tank details

For Your Reference:

1. We have the capacity of 100L, 200L, 300L, 500L, 1000L,1200L, 2000L, 3000L, 5000L, 8000L…for your reference.

material, voltage(like 380v, 50Hz, 3phases), heating method(electric, steam or gas heating), etc.

2. For electrical parts, we use SIEMENS, SCHNEIDER, DANFOSS, OMRON, ABB….etc.

3. The brewer can brew draft beer, pale beer, brown beer, stout beer etc,to meet different taste of customers.

If you have interest, please feel free to contact me.